Broke my motor lead - new motor (and wheel build) or is it replaceable ?

- Thread starter 103Alex1

- Start date

From complete wee small hours major disaster and facing up to a ruined motor to decent chance of a complete fix inside a day and everything on its way to give it a best shot... It never ceases to overwhelm me how brilliant this fourm is when you need help to fix stuff. It's like a "virtual eBike RAC". Thanks a lot guys.

A bit apprehensive about the magnets thing. I guess if I get the cable and screw bits to get the plate off then see from there that's the most sensible way forward. I might be able to get some help before Sunday but have to be completely honest (and I mean this in a caring sort of way, just truthful) .... not the most practical pairs of extra hands round here at the moment and even less experience than me lol ... so I'm not holding my breath for miracles !

Does the plate have to be oriented to line up in any particular way when you put it back that will be extra-hard to get right or can it be twisted to orient with the screw holes once it's back on against the magnet force ? It's always clearer once you're doing stuff.

OK - will put the inner screws back. The outer ones are indeed security torx screws like RobF said. I'll get a set by the end of the week hopefully - at £5 for a full set I can't complain all things considered .. and might be able to get Travelodge windows open with them as a brucie bonus !You don't need that spring thing. It's only extra support for the wire to stop it chafing.

You shouldn't remove the screws around the cassette spline. Only remove the ones around the periphery of the side-plate and then it should pop off if you tap the other end of the axle on the ground holding the wheel.

I don't think it's unnecessary to remove the side-plate from the core because the wiring is on the other side, but you need to remove the cover from the other side that has the magnets in it. For that you need help because the magnets are very strong and keep pulling it down. You must be careful not to damage the magnets especially when putting it back because it tries to jump back on with huge force as soon as it gets close. It's easier with 4 hands.

A bit apprehensive about the magnets thing. I guess if I get the cable and screw bits to get the plate off then see from there that's the most sensible way forward. I might be able to get some help before Sunday but have to be completely honest (and I mean this in a caring sort of way, just truthful) .... not the most practical pairs of extra hands round here at the moment and even less experience than me lol ... so I'm not holding my breath for miracles !

Does the plate have to be oriented to line up in any particular way when you put it back that will be extra-hard to get right or can it be twisted to orient with the screw holes once it's back on against the magnet force ? It's always clearer once you're doing stuff.

Sounds that way ... if there's enough of it left I'll probably re-use it just to be on the safe side as a precaution rather than have nothing. Can just shove some shrinkwrap up the cable from the end which will solder into the motor, feed the spring onto the new cable as it's inserted through the axle and shrink it in place beyond the axle end like it was before. Then solder up. I have a drawer full of shrinkwrap of just about every conceivable diameter now, with the exception of the big stuff you put round battery packs.You will be able to salvage the old spring when you remove the old cable.

Last edited:

D

Deleted member 4366

Guest

Count your fingers before you try that bit - And tuck in any dangly bits you don't want prunedApart from the self-pulling together by the magnets, the rest of the re-assembly is dead easy.

You got me right worried about that bit now, jackhandy ! I guess this is done by machine usually ?

It looks like we need to get into the middle bit in the centre of the copper coil array to find where the wires go and the Hall sensor / power supply connections are ?

I looked at those pics shemozzle999 linked on the Russian website ... silly question maybe, but ... where do the wires solder into and is the axle hollow right the way through from one end to the other with the wires exiting some hole in the middle ?Apart from the self-pulling together by the magnets, the rest of the re-assembly is dead easy.

It looks like we need to get into the middle bit in the centre of the copper coil array to find where the wires go and the Hall sensor / power supply connections are ?

D

Deleted member 4366

Guest

wires pass through the axle and come out a hole near the centre, then cross to the other side. All the solder joints are hidden under that aluminium casting

This is the BPM motor. I'm assuming that the CST is the same.

Scotty took his BPM apart after it got rusty. Some nice photos here. I met Scotty, who was fairly sensible and intelligent, but I don't think he had any prior experience or special skills in this area, and he didn't report any problems with dismantling. There's also a thread on ES about it, but nothing extra added other than bearing numbers:

http://www.pedelecs.co.uk/forum/electric-bicycles/10532-dirty-rusty-bafang-hub-2.html

Endless-sphere.com • View topic - Bafang BPM Dirty Greasy Rusty Motor

I just had another thought. It's possible that the wires join on the sidep-late side like this one, so it might be worth taking the side-plate off first.

Inside Bafang Geared Hub Motor - YouTube

This is the BPM motor. I'm assuming that the CST is the same.

Scotty took his BPM apart after it got rusty. Some nice photos here. I met Scotty, who was fairly sensible and intelligent, but I don't think he had any prior experience or special skills in this area, and he didn't report any problems with dismantling. There's also a thread on ES about it, but nothing extra added other than bearing numbers:

http://www.pedelecs.co.uk/forum/electric-bicycles/10532-dirty-rusty-bafang-hub-2.html

Endless-sphere.com • View topic - Bafang BPM Dirty Greasy Rusty Motor

I just had another thought. It's possible that the wires join on the sidep-late side like this one, so it might be worth taking the side-plate off first.

Inside Bafang Geared Hub Motor - YouTube

Blimey ... that was quite an insight ! Really interesting actually. Full credit to him for posting the detailed pics up too - and the bearing size specs. It's this sort of thing which other people can really benefit from if they hit maintenance or other problems  .

.

I've also picked up reading those posts that really need to have the cable pointing downwards exiting the axle hole and should seal with silicone too by the looks of it on both sides to deter water ingress. Hopefully I have some kicking around or else time to get some. There are shelves full of this sort of stuff down in Devon but bare bones only here.

Am a bit muddled by the terminology still (bearings, gaskets, planetary gears etc) and still can't visualize where the magnets actually are - haven't had time yet to sit and study what bits of an electric motor engine refer to what bits of metal in front of me So be easier once I get those darned screws off and can see.... and also where the wires run on this particular motor for the repair.

So be easier once I get those darned screws off and can see.... and also where the wires run on this particular motor for the repair.

I do remember reading a post recently but can't remember the thread where a CST got opened up and was said to be different to a Bafang - but we'll see soon for certain I guess. I'll take some pics once I can get inside the motor.

Where are those darned security torx driver bits.... oh yes - I only ordered them after 5pm today .. itching to get that thing open now !

.. itching to get that thing open now !

I've also picked up reading those posts that really need to have the cable pointing downwards exiting the axle hole and should seal with silicone too by the looks of it on both sides to deter water ingress. Hopefully I have some kicking around or else time to get some. There are shelves full of this sort of stuff down in Devon but bare bones only here.

Am a bit muddled by the terminology still (bearings, gaskets, planetary gears etc) and still can't visualize where the magnets actually are - haven't had time yet to sit and study what bits of an electric motor engine refer to what bits of metal in front of me

I do remember reading a post recently but can't remember the thread where a CST got opened up and was said to be different to a Bafang - but we'll see soon for certain I guess. I'll take some pics once I can get inside the motor.

Where are those darned security torx driver bits.... oh yes - I only ordered them after 5pm today

Last edited:

Good to see you're back on it Alex and seeing it more as just another challenge...these little setbacks as annoying as they are, when you're anxious to get riding, can be useful learning experiences and interesting little challenges in themselves. At least if this happens again to someone else, they'll be able to learn from your postsBlimey ... that was quite an insight ! Really interesting actually. Full credit to him for posting the detailed pics up too - and the bearing size specs. It's this sort of thing which other people can really benefit from if they hit maintenance or other problems.

I've also picked up reading those posts that really need to have the cable pointing downwards exiting the axle hole and should seal with silicone too by the looks of it on both sides to deter water ingress. Hopefully I have some kicking around or else time to get some. There are shelves full of this sort of stuff down in Devon but bare bones only here.

Am a bit muddled by the terminology still (bearings, gaskets, planetary gears etc) and still can't visualize where the magnets actually are - haven't had time yet to sit and study what bits of an electric motor engine refer to what bits of metal in front of meSo be easier once I get those darned screws off and can see.... and also where the wires run on this particular motor for the repair.

I do remember reading a post recently but can't remember the thread where a CST got opened up and was said to be different to a Bafang - but we'll see soon for certain I guess. I'll take some pics once I can get inside the motor.

Where are those darned security torx driver bits.... oh yes - I only ordered them after 5pm today.. itching to get that thing open now !

Where in Devon are you Alex?

I have rebuilt a BPM that had a broken shaft. The phase wires will need joining to the windings and lacing/glueing inplace. You will have to pull the stator free of the magnets. Not difficult, but you have to beware of the forces involved. Does the motor have hall sensors?

If you get stuck, i'm in somerset and can give you some assistance to repair it.

I have rebuilt a BPM that had a broken shaft. The phase wires will need joining to the windings and lacing/glueing inplace. You will have to pull the stator free of the magnets. Not difficult, but you have to beware of the forces involved. Does the motor have hall sensors?

If you get stuck, i'm in somerset and can give you some assistance to repair it.

D

Deleted member 4366

Guest

John, you seem to be undoing those screws around the outside. If you take them all out, can you remove the aluminium casting leaving the magnets in place?

Akex the magnets are flat and there's loads of them in a ring under those screws around the outside in that photo. In most other motors you don't have those screws, so you'd just pull that aluminium casting upwards while holding down the axle in a vice and off it comes when you pull harder than the magnets. It's not to difficult to get off, but you have to be careful putting it back because as soon as you get close, it jumps down, and if it's crooked, you smash the corners off the magnets; however, it does tend to self-centralise.

Terminology:

Rotor - the aluminium casting with magnets that spins round the stator

Stator - the bit with the coils of wire that's attached to the axle, so stays still.

Planetary gears - the three plastic gears that spin round the sun gear

Sun gear - the smaller gear that's attached to the aluminium casting (rotor)

Gasket - something on a joint that stops water getting in or oil getting out

Bearing - something that allows something else to spin without wearing out. Sometimes ball-races or rollers, sometimes a plain bush (tube) made out of a copper alloy or plastic.

Akex the magnets are flat and there's loads of them in a ring under those screws around the outside in that photo. In most other motors you don't have those screws, so you'd just pull that aluminium casting upwards while holding down the axle in a vice and off it comes when you pull harder than the magnets. It's not to difficult to get off, but you have to be careful putting it back because as soon as you get close, it jumps down, and if it's crooked, you smash the corners off the magnets; however, it does tend to self-centralise.

Terminology:

Rotor - the aluminium casting with magnets that spins round the stator

Stator - the bit with the coils of wire that's attached to the axle, so stays still.

Planetary gears - the three plastic gears that spin round the sun gear

Sun gear - the smaller gear that's attached to the aluminium casting (rotor)

Gasket - something on a joint that stops water getting in or oil getting out

Bearing - something that allows something else to spin without wearing out. Sometimes ball-races or rollers, sometimes a plain bush (tube) made out of a copper alloy or plastic.

Last edited by a moderator:

Couldn't wait for Amazon to get those bits to me ... tried B&Q (phone) as many miles on the bike round trip - none. Maplins came up trumps ... these ones have the holes in and got the screws out (you need a T20) :

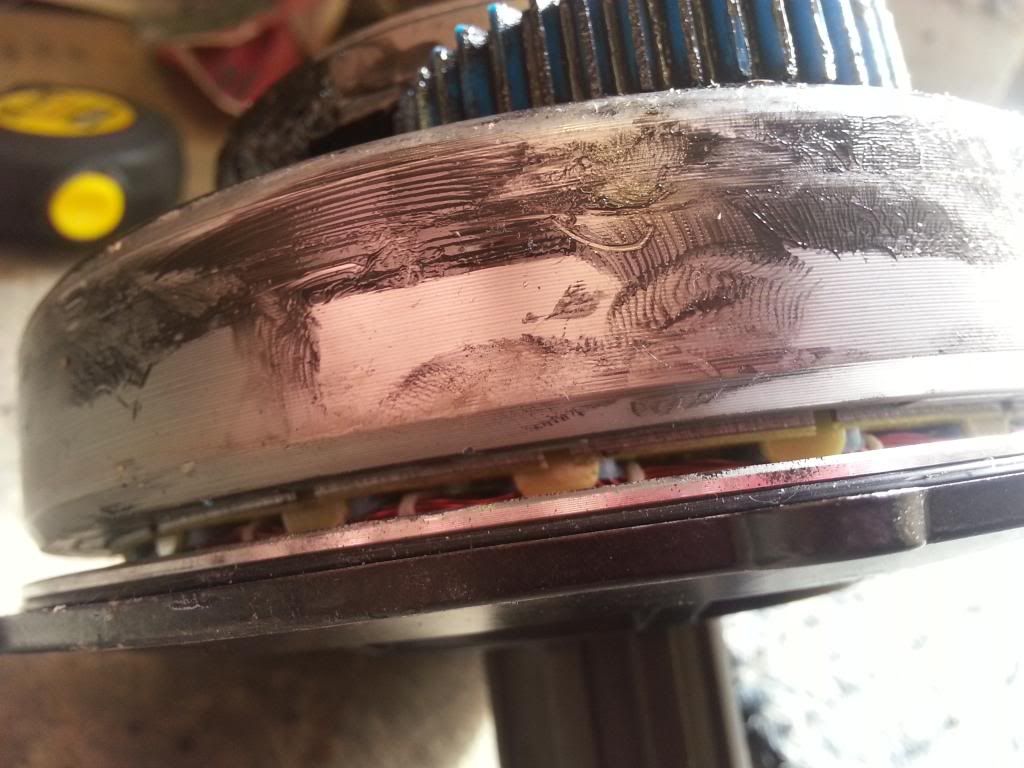

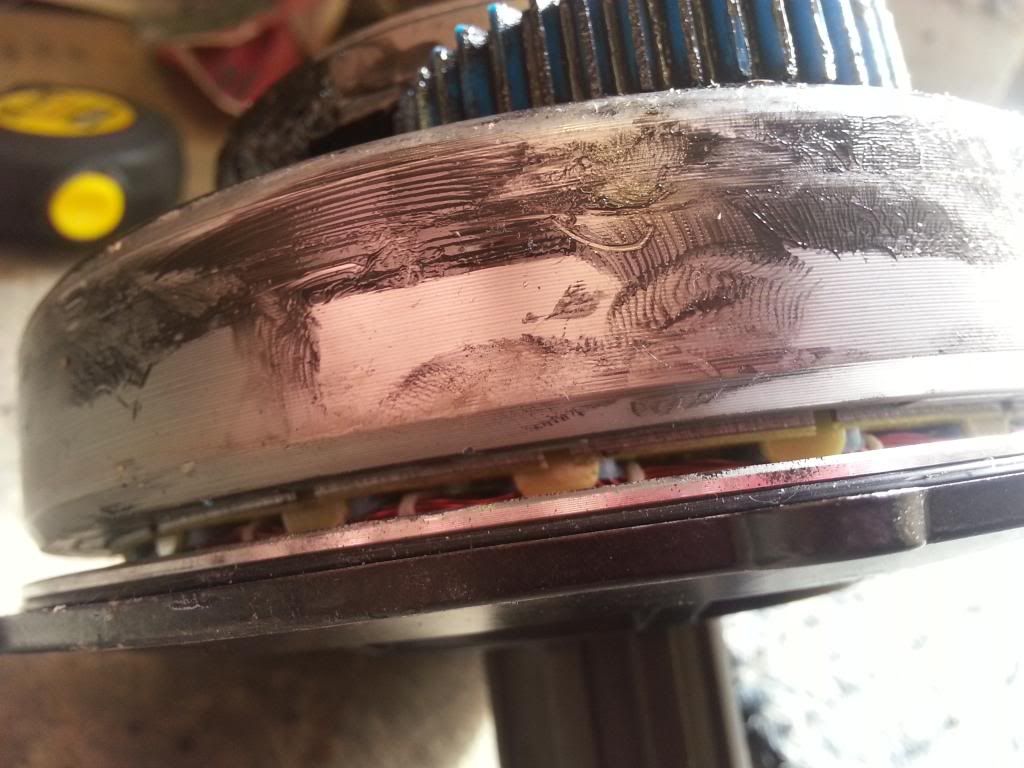

So ... got the core out (casing is left laced in the wheel) :

pics of the inside of one brand new CST 500W :

1st thing which strikes me - there's no ring of screws around the outside of the part which the magnets and coils are beneath (it's hard to see on the photo for the ring of grease) so in that respect this is definitely a bit different to the BPM.

Instead of using a vice could 2 pairs of hands pull it apart ? I'm on my own until this evening if so, else can try to source a suitable vice if they are affordable and obtainable. I'm going to need something to hold wood at some point. Again, have one attached permanently to a workbench in Devon but can't get down there for a couple of weeks - and have to clear half a garage to get to the bench ! Tools you don't use for months always seem to be in the wrong place when you need 'em !

....EDIT :- just a thought ... won't the plate on the other side lever off with a crowbar like you use to lift manhole covers ? Or will that just risk damaging magnets or stuff near the edges ?

So ... got the core out (casing is left laced in the wheel) :

pics of the inside of one brand new CST 500W :

1st thing which strikes me - there's no ring of screws around the outside of the part which the magnets and coils are beneath (it's hard to see on the photo for the ring of grease) so in that respect this is definitely a bit different to the BPM.

Instead of using a vice could 2 pairs of hands pull it apart ? I'm on my own until this evening if so, else can try to source a suitable vice if they are affordable and obtainable. I'm going to need something to hold wood at some point. Again, have one attached permanently to a workbench in Devon but can't get down there for a couple of weeks - and have to clear half a garage to get to the bench ! Tools you don't use for months always seem to be in the wrong place when you need 'em !

....EDIT :- just a thought ... won't the plate on the other side lever off with a crowbar like you use to lift manhole covers ? Or will that just risk damaging magnets or stuff near the edges ?

Last edited:

Find an old pot or tin the same diameter of the end plate and deep enough to take the motor.

Drop the motor onto the tin so that the end plate is supported all round and then double nut the shaft end and gently tap down on the nut to press the end plate off the shaft.

Drop the motor onto the tin so that the end plate is supported all round and then double nut the shaft end and gently tap down on the nut to press the end plate off the shaft.

D

Deleted member 4366

Guest

... or two chairs back to back, two piles of bricks or anything like that. Try not to rest on the screw-holes because they might break off. Once you've got something supporting the side-plate, the axle will tap through with gravity helping it, but don't forget to catch the motor if it's got a long way to drop.

You can take of the clutch and planetary gears now. undo that nut on the axle and it should slide off. Lay all the bits out in sequence as you disassemble so that you no the sequence for re-assembly.

This reminds me of those surgeons that do keyhole surgery by remote control from a different location, only they can see what's happening by camera.

Have you got Skype, Alex?

You can take of the clutch and planetary gears now. undo that nut on the axle and it should slide off. Lay all the bits out in sequence as you disassemble so that you no the sequence for re-assembly.

This reminds me of those surgeons that do keyhole surgery by remote control from a different location, only they can see what's happening by camera.

Have you got Skype, Alex?

Last edited by a moderator:

I've popped a wide bladed wood carving tool between the plate which has the cassette bit in the middle and the rest of the motor core, and levered up a bit.

Not sure if I should carry on doing it this way - are the magnets supposed to stay inside the core when I pull the plate further off ? The coils seem to be coming with the plate as I start separating it.

Might be clearer from these :

!

!  There is a nut screwed onto the axle inside the head of the cassette spline that's on the same side as the plate.

There is a nut screwed onto the axle inside the head of the cassette spline that's on the same side as the plate.

There's another nut over the axle on the other side in effect I securing the rest of the core to the axle (I think)

Was I supposed to take off the nut from the non-drive side or do anything with the attached gears etc. before looking to separate the plate on the cassette side ?

Not sure if I should carry on doing it this way - are the magnets supposed to stay inside the core when I pull the plate further off ? The coils seem to be coming with the plate as I start separating it.

Might be clearer from these :

Not sure what you mean m8, sorrythen double nut the shaft end and gently tap down on the nut to press the end plate off the shaft.

There's another nut over the axle on the other side in effect I securing the rest of the core to the axle (I think)

Was I supposed to take off the nut from the non-drive side or do anything with the attached gears etc. before looking to separate the plate on the cassette side ?

D

Deleted member 4366

Guest

Don't lever it like that any more. You can do some serious damage. Just rest it on two bricks or similar and tap it through. Look at my last post which I edited probably after you read it

Ah - you tap the axle ... sorry had misunderstood what to tap. Yeah I don't have anything the same diameter so had it on the top of a paint tin on one side and on the top of a step on the other with a pile of rags under to catch it - but couldn't see any nut which could be tapped with a hammer lol.... or two chairs back to back, two piles of bricks or anything like that. Try not to rest on the screw-holes because they might break off. Once you've got something supporting the side-plate, the axle will tap through with gravity helping it, but don't forget to catch the motor if it's got a long way to drop.

I'll take the gears etc. off first will be easier to see what I'm doing.

I did have Skype on my old laptop, Dave but not on this one - I can try to install it (haven't used it since my old machine broke) and see if I can remember my login or else set up a new account. Should probably have it anyway.

This reminds me of those surgeons that do keyhole surgery by remote control from a different location, only they can see what's happening by camera.

EDIT : Postie has just brought the replacement cable. It's exactly the same as the one in there by the looks of it. Thanks a lot Morphix

Last edited:

I'm not back down there for a while, wurly - am building the bike elsewhere and going to send it down there when I've built it so I've got it to use when I'm there. Far South West of the county.Where in Devon are you Alex?

I have rebuilt a BPM that had a broken shaft. The phase wires will need joining to the windings and lacing/glueing inplace. You will have to pull the stator free of the magnets. Not difficult, but you have to beware of the forces involved. Does the motor have hall sensors?

If you get stuck, i'm in somerset and can give you some assistance to repair it.

Thanks a lot for the offer of help - fingers crossed I'll get it sorted but if I'm stuck that's very kind of you. Yes, the motor has Hall sensors.

D8evh I was refitting the screws after one had come loose and fallen inside the motor and was causing a loud rattle, so I didn't go any further with the strip down, worth checking because I found another 4 loose screws.

Last edited:

Related Articles

-

MTF Enterprises announces acquisition of EMU Electric Bikes

MTF Enterprises announces acquisition of EMU Electric Bikes- Started by: Pedelecs

-

Wisper 806T folding bike wins Which? ‘Best Buy’

Wisper 806T folding bike wins Which? ‘Best Buy’- Started by: Pedelecs

-

Sustrans calls for protected cycle lanes

Sustrans calls for protected cycle lanes- Started by: Pedelecs

-

Amazon launch their first UK e-cargo micromobility hub

Amazon launch their first UK e-cargo micromobility hub- Started by: Pedelecs