mounting a hub-motor, torque-arm, .. man thats hard work

- Thread starter kraeuterbutter

- Start date

no progress in the moment..

had to lear for some exams..

however:

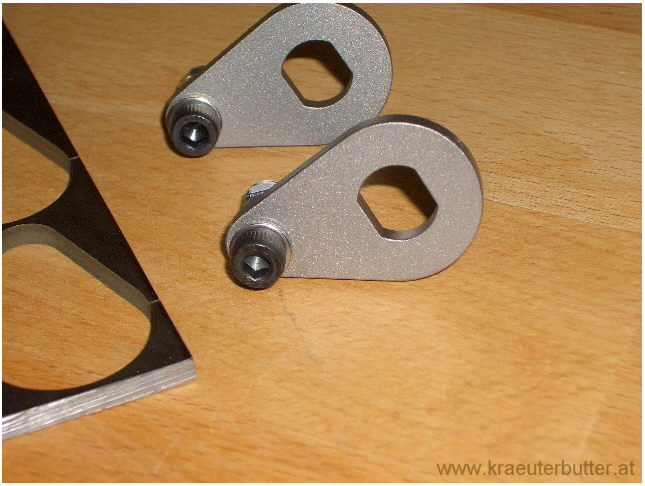

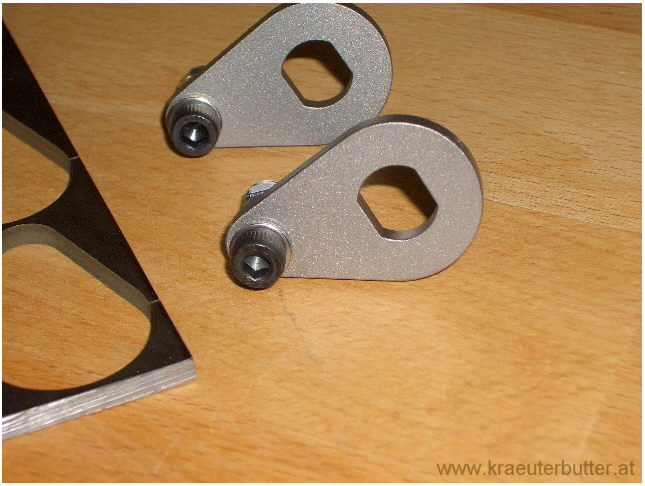

my buddy sent me this today, thats how he will make it..

he will make it this week, so i can mount it the coming weekend..

had to lear for some exams..

however:

my buddy sent me this today, thats how he will make it..

he will make it this week, so i can mount it the coming weekend..

Hi kraeuterbutter,

Good luck with the exams.

That is so similar to what I made last weekend for my new project.

I only had some 30 mm wide steel strip. There is room on the bike for bigger ones and next time I will try to get some wider plate in stainless steel. On a milling machine, you cannot make it exactly as drawn - you cannot make the 12 mm diameter ends on the slot. The production ones are made by stamping or punching out of a sheet.

Nick

Good luck with the exams.

That is so similar to what I made last weekend for my new project.

I only had some 30 mm wide steel strip. There is room on the bike for bigger ones and next time I will try to get some wider plate in stainless steel. On a milling machine, you cannot make it exactly as drawn - you cannot make the 12 mm diameter ends on the slot. The production ones are made by stamping or punching out of a sheet.

Nick

Last edited:

It's easy if you use a 12mm slot drill, Nick..you cannot make the 12 mm diameter ends on the slot. The production ones are made by stamping or punching out of a sheet.

No, that sounds like a job for a CNC machine. I had a vice on top of a rotary table on top of the milling bed. At least it was more challenging than doing it with a file.Have you tried working both axes together, Nick? It's an interesting exercise in coordination

Yes, the same Miles.

Nick

I made mine by using a 5mm slot drill to do a 10mm square hole, then stuck a 10mm slot drill in to approximate the end radius (which is really 6mm radius),

This made a fairly good fit on the shaft, although was a pig to machine, as I chose to use a bit of scrap 10g 316 stainless that I had lying in the corner of the workshop. I really detest machining stainless, especially as my small vertical milling machine doesn't have a particularly slow speed option. I keep promising myself a new machine, but the cost of something half-decent is too much for the odd hobby job.

Jeremy

This made a fairly good fit on the shaft, although was a pig to machine, as I chose to use a bit of scrap 10g 316 stainless that I had lying in the corner of the workshop. I really detest machining stainless, especially as my small vertical milling machine doesn't have a particularly slow speed option. I keep promising myself a new machine, but the cost of something half-decent is too much for the odd hobby job.

Jeremy

so..

now there was some progress:

cut with an "endless wire"...

and sandblasted

thanxs to my flying buddy Jochen

(thats him, when he helped me, to convert my 3,5ccm 1:8 scale nitro-buggy to brushless electric)

so: mounted to the bike:

it was a perfect fit from the very first second

now there was some progress:

cut with an "endless wire"...

and sandblasted

thanxs to my flying buddy Jochen

(thats him, when he helped me, to convert my 3,5ccm 1:8 scale nitro-buggy to brushless electric)

so: mounted to the bike:

it was a perfect fit from the very first second

oh...

and meanwhile i have also done some of the wiring..

i will do all the wiring inside the frame:

thats how i make it:

first step is done by an hoover (vacuum cleaner)

the rest i think is self-explanatory from the pictures

and meanwhile i have also done some of the wiring..

i will do all the wiring inside the frame:

thats how i make it:

first step is done by an hoover (vacuum cleaner)

the rest i think is self-explanatory from the pictures

when i was on the RC-flying field and Jochen was giving the parts to me,

my buddies said,

that the parts will be the most luxurious/precious part by far on the whole bike..

(iam well known for fixing every problem normally with adhesive tape...

thats also how most of my rc-planes look like )

)

my buddies said,

that the parts will be the most luxurious/precious part by far on the whole bike..

(iam well known for fixing every problem normally with adhesive tape...

thats also how most of my rc-planes look like

so..

meanwhile we have a German Pedelec-forum as well, so i was most time there..

little update:

its working !!!

here a first little video:

YouTube - mein Elektrobike mit 13s1p Fepo4 2300mah

the hill in the middle of the video is 20%

on the left side of that hill it is 30%, its the one i drive down later

the bike makes it up this hill as well..

Setup ?

42,9V nominal 13s1p Fepo4 with 2.3Ah

the battery stays absolut cool, the motor as well,

only the controller gets warm..

also interesting finding:

with 14,8V battery and rc-modell-controller i have more torque than with 42V and bikecontroller..

how can this be ?

bike-controller: 14A limit

wereas i get ~25A with the 14,8V and rc-plane-controller (which stays also absolutely cool)

yes, looks not that nice with the battery there (just for testing, two RC-Heli-batteries which result in 13s1p)

batteryweight: 996g

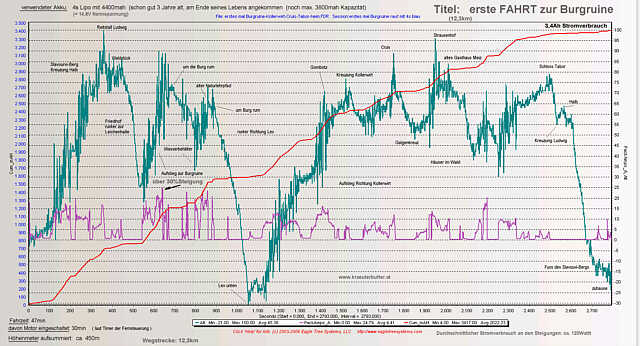

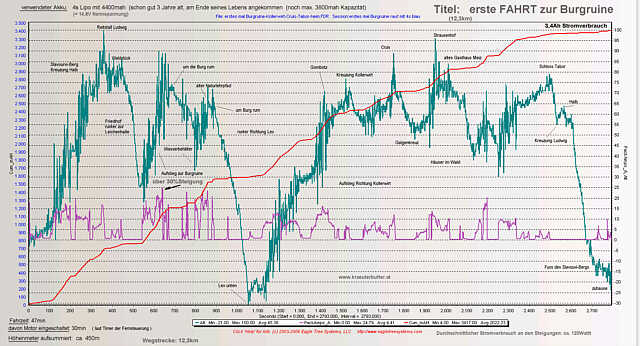

here a little eagle-tree-measuring with

14,8Volt

=> 12km tripp

=> made ~450meters of hight

=> used only 3.4Ah from the 14,8Volt-4,4Ah batterypack

http://www.kraeuterbutter.at/Bilder2/Radnabenmotor_Vorderreifen/Testlauf 3/MESSUNG_erstesmal Burgruine _ Beschriftet.jpg

meanwhile we have a German Pedelec-forum as well, so i was most time there..

little update:

its working !!!

here a first little video:

YouTube - mein Elektrobike mit 13s1p Fepo4 2300mah

the hill in the middle of the video is 20%

on the left side of that hill it is 30%, its the one i drive down later

the bike makes it up this hill as well..

Setup ?

42,9V nominal 13s1p Fepo4 with 2.3Ah

the battery stays absolut cool, the motor as well,

only the controller gets warm..

also interesting finding:

with 14,8V battery and rc-modell-controller i have more torque than with 42V and bikecontroller..

how can this be ?

bike-controller: 14A limit

wereas i get ~25A with the 14,8V and rc-plane-controller (which stays also absolutely cool)

yes, looks not that nice with the battery there (just for testing, two RC-Heli-batteries which result in 13s1p)

batteryweight: 996g

here a little eagle-tree-measuring with

14,8Volt

=> 12km tripp

=> made ~450meters of hight

=> used only 3.4Ah from the 14,8Volt-4,4Ah batterypack

http://www.kraeuterbutter.at/Bilder2/Radnabenmotor_Vorderreifen/Testlauf 3/MESSUNG_erstesmal Burgruine _ Beschriftet.jpg

Last edited:

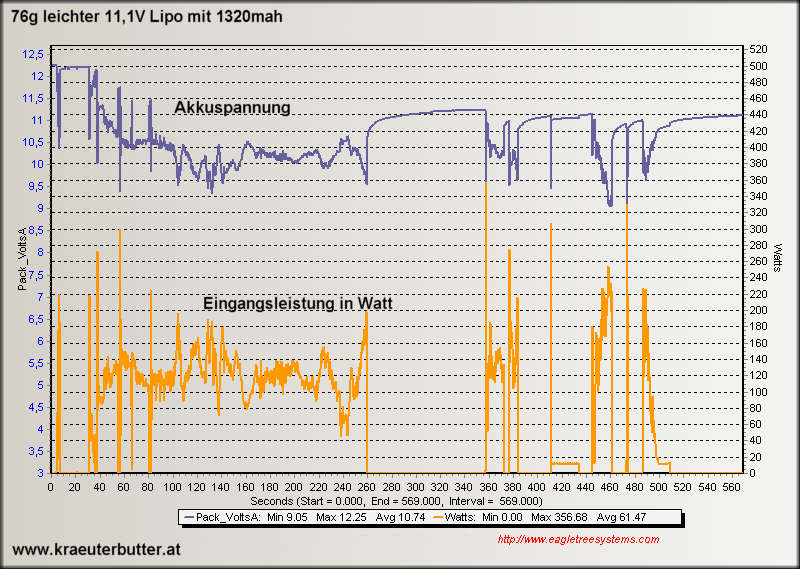

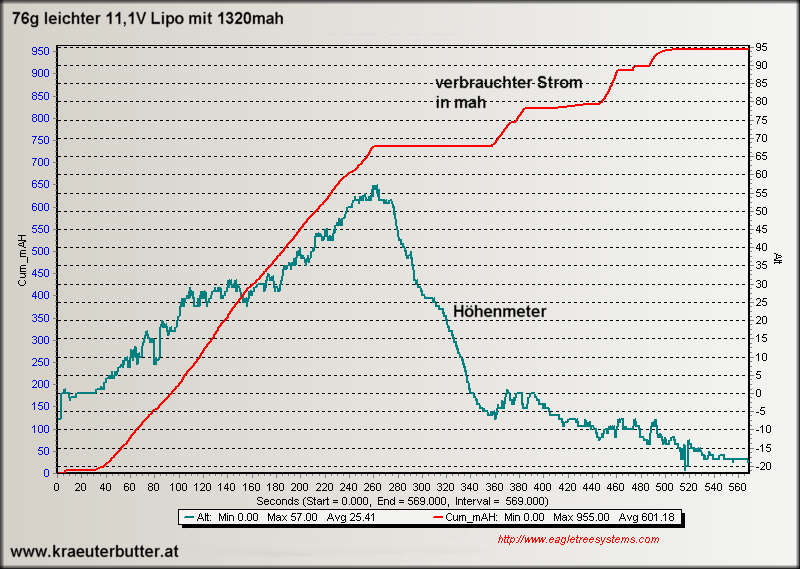

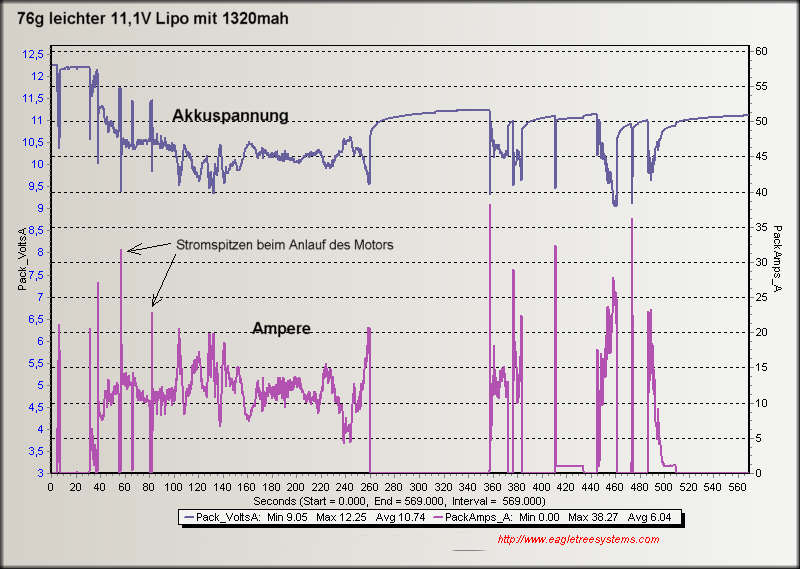

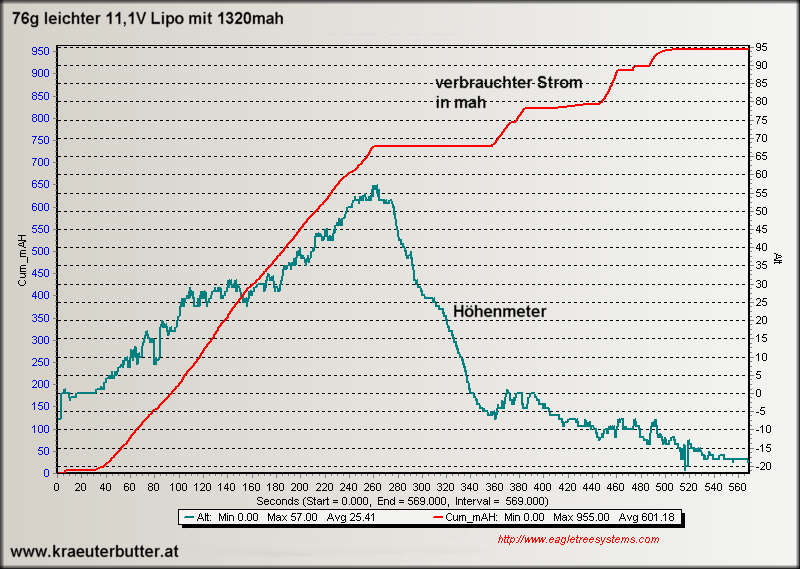

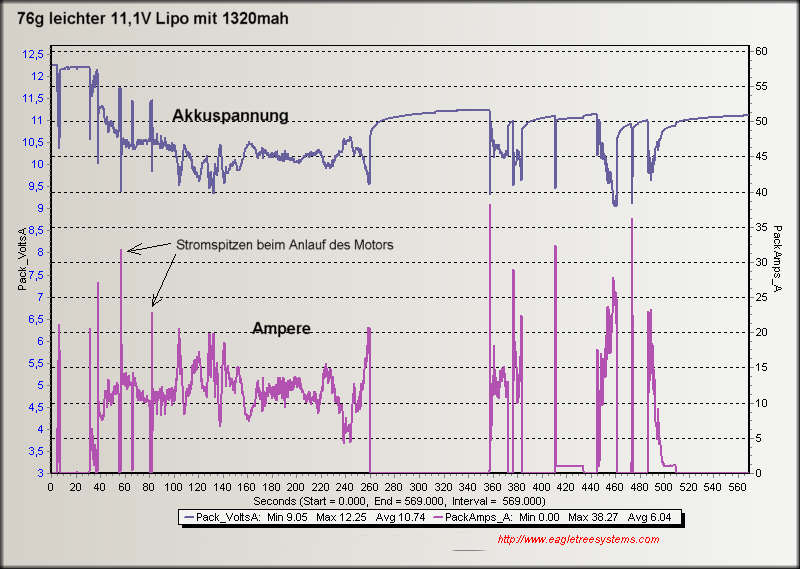

hey, i also tried this little battery from an rc-plane:

yes, realy small (halfe the size of cigarettes)

the yellow color is wood, i surrounded the battery with that for protection against penetration

it weights only 76g !!

11,1Volt and 1350mah

here what i measured:

not bad, isn´t it ?

the hill is a 60m (height) in 550m or how you call that

on some places its between 15,5% and 20,5%

can you see the battery on the bike ?

here the diagramms:

i can make about 120m of height (~ 360 feet) with this little 76g battery !

current and voltage:

you see, this 20A are the limit for that little (nearly 3 years old and so out-to-date) battery

meanwhile there are lipos with same size that can do double currents

yes, realy small (halfe the size of cigarettes)

the yellow color is wood, i surrounded the battery with that for protection against penetration

it weights only 76g !!

11,1Volt and 1350mah

here what i measured:

not bad, isn´t it ?

the hill is a 60m (height) in 550m or how you call that

on some places its between 15,5% and 20,5%

can you see the battery on the bike ?

here the diagramms:

i can make about 120m of height (~ 360 feet) with this little 76g battery !

current and voltage:

you see, this 20A are the limit for that little (nearly 3 years old and so out-to-date) battery

meanwhile there are lipos with same size that can do double currents

Last edited:

as i said, an interesting finding was:

on (steep) hills, more power with 14,8Volt or 18Volt batteries, than with the 42V Battery and the bike-controller (with current limit)

often you hear people: "i have hills, so i need 36V instead of 24V or 48V instead of 24V)

for that bafang-motor i have its not true..

look here:

click for bigger, more details:

http://www.kraeuterbutter.at/Bilder2/Radnabenmotor_Vorderreifen/Testlauf 3/MESSUNG_erstesmal Burgruine _ Beschriftet.jpg

on that over 30% hill at our castle i saw current of 25A with that 14,8V battery

with 42V the currents would be MUCH MUCH higher, it would burn the motor emediatley (60A and more)

so for that reason, there is a current-limiter in the bike-controller, which limits the current to 14A

how does it do this ?

it reduces Throttle more and more...

so: when i see 25A with the 14,8V-battery an rc-planecontroller without current-limitator,

than the bike-controller must reduce the 42V to a voltage much lower than 14,8V, so the amps are only 14A

result: i have only half (or less) power than with the 14,8V setup

so why not use 14,8V instead of 42V ?

hmm... why not..

seriously, iam considiring to drive in future with much less volt than with 42V

the downside of 14,8V: it drives only ~15km/h

the best thing would be: two batteries in series for going flat and fast

and for hills paralleling the batteries and a much higher amp-limit-setting (maybe 30A)

on (steep) hills, more power with 14,8Volt or 18Volt batteries, than with the 42V Battery and the bike-controller (with current limit)

often you hear people: "i have hills, so i need 36V instead of 24V or 48V instead of 24V)

for that bafang-motor i have its not true..

look here:

click for bigger, more details:

http://www.kraeuterbutter.at/Bilder2/Radnabenmotor_Vorderreifen/Testlauf 3/MESSUNG_erstesmal Burgruine _ Beschriftet.jpg

on that over 30% hill at our castle i saw current of 25A with that 14,8V battery

with 42V the currents would be MUCH MUCH higher, it would burn the motor emediatley (60A and more)

so for that reason, there is a current-limiter in the bike-controller, which limits the current to 14A

how does it do this ?

it reduces Throttle more and more...

so: when i see 25A with the 14,8V-battery an rc-planecontroller without current-limitator,

than the bike-controller must reduce the 42V to a voltage much lower than 14,8V, so the amps are only 14A

result: i have only half (or less) power than with the 14,8V setup

so why not use 14,8V instead of 42V ?

hmm... why not..

seriously, iam considiring to drive in future with much less volt than with 42V

the downside of 14,8V: it drives only ~15km/h

the best thing would be: two batteries in series for going flat and fast

and for hills paralleling the batteries and a much higher amp-limit-setting (maybe 30A)

Lots of interesting info there.

Can't be doing that little battery much good pulling that many amps though can it?

Can't be doing that little battery much good pulling that many amps though can it?

yes, its for sure not "good" for the cell

but its normal treatment in rc-hobby-world..

we are used to the fact that batteries last between 50-150cycles.

here a test of this very same cell in labor:

Elektromodellflug - Thunder Power - LiPos im Test

as said: out-of-date meanwhile.. there are better cells

that can do 45Amps in the same leage

but its normal treatment in rc-hobby-world..

we are used to the fact that batteries last between 50-150cycles.

here a test of this very same cell in labor:

Elektromodellflug - Thunder Power - LiPos im Test

as said: out-of-date meanwhile.. there are better cells

that can do 45Amps in the same leage

Related Articles

-

MTF Enterprises announces acquisition of EMU Electric Bikes

MTF Enterprises announces acquisition of EMU Electric Bikes- Started by: Pedelecs

-

Wisper 806T folding bike wins Which? ‘Best Buy’

Wisper 806T folding bike wins Which? ‘Best Buy’- Started by: Pedelecs

-

Sustrans calls for protected cycle lanes

Sustrans calls for protected cycle lanes- Started by: Pedelecs

-

Amazon launch their first UK e-cargo micromobility hub

Amazon launch their first UK e-cargo micromobility hub- Started by: Pedelecs