My name is ..... And I'm new here.....

- Thread starter FastFreddy2

- Start date

I'd already guessed that was the case, virtually all estimates of steepness are greatly exaggerated. The BPM in a 20" rim geared for 11 mph will handle that ok. My equivalent e-bike, but motor geared for 15.5 mph, climbed the 14% hill to my home almost unaided by me. It would do an unaided standing start up 12%.The slope was measured today, and is not as bad as I thought statistically, but was really unpleasant to peddle up. The rise was a 8% slope at it's best, typically 12-14% and in the worst places 16-18%. Considerably better than the 20/25% I had mentioned before.

The BPM will climb that at the optimum of torque and power at about 6mph taking about 4 minutes for the 375 metres, with a touch of help from your lady only at the steepest points. I'm assuming she is able to give some moderate assistance. If she can't give any, the e-bike approach with the Kettweisel is too flawed.

The one problem might be wheel spin with the low up front weight, but things can be done about that at any points when it occurs:

1) Ease off the throttle.

2) Use level 4 instead of 5 if it occurs.

3) Add some ballast weight up front.

4) Use a wider tyre with maximum rubber to tarmac area for best adhesion.

.

Last edited:

Maybe some of the non slip strips that are sold for decking. These are hard resin strips with a coarse grit embedded. They could be screwed down?

With hindsight, I think there may have been a case for (i) either opting for a tadpole style and finding a way to get a non-standard seat fitted that allowed a higher recumbent position, or (ii) waiting for a used STEPS version to materialise, maybe including a search in 'near' Europe, like Holland. Belgium, Germany, and possibly France. As has been suggested, the Shimano motors have an appalling reliability problem, and finding a STEPS version with a junk motor might have been possible.The BPM will climb that at the optimum of torque and power at about 6mph taking about 4 minutes for the 375 metres, with a touch of help from your lady only at the steepest points. I'm assuming she is able to give some moderate assistance. If she can't give any, the e-bike approach with the Kettweisel is too flawed.

The one problem might be wheel spin with the low up front weight, but things can be done about that at any points when it occurs:

1) Ease off the throttle.

2) Use level 4 instead of 5 if it occurs.

3) Add some ballast weight up front.

4) Use a wider tyre with maximum rubber to tarmac area for best adhesion.

.

If this project had been pursued by someone with what looked like a long life in front of them, the decision on what the base vehicle could be, might have been more inclusive, and time would have allowed more vehicles to be tried/considered. As it was (is), covid already caused delays, and lack of readily available choice in the South meant grabbing the first thing that came along that ticked enough boxes. The Hase products offer a higher sitting/reclining position than the tadpole style competition. There is another Taiwan based product called the Performer Futuro, that looked promising, but a mid-drive on that didn't look immediately possible either.

"We" are hoping to find a way to place the battery as close to the front wheel as possible, on the boom. This may mean some over-engineered mounting brackets for a low slung battery, or some equally over-engineered mountings for the battery to sit almost over the front wheel. This is going to be, or this version is going to be, a fairly unique "first off" unless someone comes along in the next 2-3 weeks and has an alternative. After that time, money will have been spent.

The wheel and tyre combo presents something of a challenge too. Unsurprisingly, 26", 27.5" 28/29/700 wheel sizes come in a wide range from pencil thin road rims, to downhill rims that would drain the energy from anyone trying to use them for riding up a hill. Mr Woosh maybe able to help with that choice.

Tyres, need to be largely puncture resistant, slightly knobbly for use on hardpack and grass, and as wide as we can get them on what will be the rim choice. Widest I found this morning that suits this description in folding; is Schwalbe Rocket Ron at 2.25, and wired Smart Sam at 2.35, both in 20" of course. These are plenty wide enough for road, but pretty much a starting point for offroad or loose terrain. It's all a compromise!

All agreed. A tadpole would have been a much more suitable option, but there's few with higher seat positions.With hindsight, I think there may have been a case for (i) either opting for a tadpole style and finding a way to get a non-standard seat fitted that allowed a higher recumbent position, or (ii) waiting for a used STEPS version to materialise, maybe including a search in 'near' Europe, like Holland. Belgium, Germany, and possibly France. As has been suggested, the Shimano motors have an appalling reliability problem, and finding a STEPS version with a junk motor might have been possible.

If this project had been pursued by someone with what looked like a long life in front of them, the decision on what the base vehicle could be, might have been more inclusive, and time would have allowed more vehicles to be tried/considered. As it was (is), covid already caused delays, and lack of readily available choice in the South meant grabbing the first thing that came along that ticked enough boxes. The Hase products offer a higher sitting/reclining position than the tadpole style competition. There is another Taiwan based product called the Performer Futuro, that looked promising, but a mid-drive on that didn't look immediately possible either.

View attachment 51264

"We" are hoping to find a way to place the battery as close to the front wheel as possible, on the boom. This may mean some over-engineered mounting brackets for a low slung battery, or some equally over-engineered mountings for the battery to sit almost over the front wheel. This is going to be, or this version is going to be, a fairly unique "first off" unless someone comes along in the next 2-3 weeks and has an alternative. After that time, money will have been spent.

The wheel and tyre combo presents something of a challenge too. Unsurprisingly, 26", 27.5" 28/29/700 wheel sizes come in a wide range from pencil thin road rims, to downhill rims that would drain the energy from anyone trying to use them for riding up a hill. Mr Woosh maybe able to help with that choice.

Tyres, need to be largely puncture resistant, slightly knobbly for use on hardpack and grass, and as wide as we can get them on what will be the rim choice. Widest I found this morning that suits this description in folding; is Schwalbe Rocket Ron at 2.25, and wired Smart Sam at 2.35, both in 20" of course. These are plenty wide enough for road, but pretty much a starting point for offroad or loose terrain. It's all a compromise!

Spending on the Kettweiser conversion is a risk, though I'm sure the motor option is solved so long as your lady can give some moderate input to the rear at times.

It's the front drive with such little front weight that concerns me most since it's so far from ideal. The battery over the front wheel will help, but we can't know if that will work sufficiently well until the money is spent.

Certainly if it were me I wouldn't take the risk, preferring to hold out for a tadpole with a mid/front motor, even if it meant modifying that by raising the seat somewhat.

.

It now seems the BPM motor is not as available as first thought.Look forward to reports of hub motor successful outcome!

I have about 20 front BPM in 26" rims in stock , they are spare parts for our Big Bear bikes. Email support@wooshbikes.co.uk if you are interested. I'll make the kit for your recumbent.

Last edited:

I am completely confused by this reply.I have about 20 front BPM in 26" rims in stock , they are spare parts for our Big Bear bikes. Email support@wooshbikes.co.uk if you are interested. I'll make the kit for your recumbent.

This afternoon I got an email from someone in your company who told me there was no stock of the BPM hub motor, and little to no prospect of getting one. That being the case, I am trying to source a MAC 536HF (12) instead..... A much more expensive, and also elusive hub motor.

AliExpress?

www.aliexpress.com

www.aliexpress.com

140.76£ 10% OFF|Bafang motor BPM / BPM2 bafang 48V500W Rear Motor Hub Motor bafang ebike DIY brushless motor|Electric Bicycle Accessories| - AliExpress

Smarter Shopping, Better Living! Aliexpress.com

Looking for a front one?AliExpress?

140.76£ 10% OFF|Bafang motor BPM / BPM2 bafang 48V500W Rear Motor Hub Motor bafang ebike DIY brushless motor|Electric Bicycle Accessories| - AliExpress

Smarter Shopping, Better Living! Aliexpress.comwww.aliexpress.com

People smarter than me would have to say that is suitable.

The email would have been about motor only out of stock. The Woosh person posting here is offering to strip off the rim from a new stock spare wheel BPM for the bikes they've previously sold and build a 20" one specifically to solve your problem, Great service, go for it.I am completely confused by this reply.

This afternoon I got an email from someone in your company who told me there was no stock of the BPM hub motor, and little to no prospect of getting one. That being the case, I am trying to source a MAC 536HF (12) instead..... A much more expensive, and also elusive hub motor.

.

If you decide to order, pay using Paypal - for me, getting AliExpress to refund has been impossible (for somewhat lower value headphone earpads).Looking for a front one?

People smarter than me would have to say that is suitable.

Free shipping BPM 36v 500w Electric bicycle hub motor geared design front or rear 500w bpm motor - AliExpress 18

Smarter Shopping, Better Living! Aliexpress.com

it's probably Andy who replied to you. We don't sell parts and your project is a one off.This afternoon I got an email from someone in your company who told me there was no stock of the BPM hub motor, and little to no prospect of getting one. That being the case, I am trying to source a MAC 536HF (12) instead..... A much more expensive, and also elusive hub motor.

We used to sell BPM front hub kits but they are messy:

https://wooshbikes.co.uk/?hubkits#frontbpmkit

We also keep BPM motors with 3-pin cable, 6-pin cable and 9-pin cable. All in 26" rims.

They are for different generations of our Big Bear bikes. https://wooshbikes.co.uk/?bigbearplus

Please email me directly, tony@wooshbikes.co.uk. I will go see Andy about your project.

Don't forget to include pictures, general trike, handlebars, bottom bracket area, where you want the battery.

Last edited:

It was.it's probably Andy who replied to you.

That isn't instilling confidence? The correspondence I have been having with Andy, has never mentioned "bits" of a kit, it's always been 'motor/controller/battery', and I have sent pictures regarding this already.We don't sell parts and your project is a one off.

We used to sell BPM front hub kits but they are messy:

Hopefully, some time tomorrow I will forward to you all the correspondence (email) that has been exchanged previously. Assuming you haven't seen it already (via Andy). Forwarding all there is to forward, isn't a 5 minute job, and I have a lot on tomorrow already.Please email me directly, tony@wooshbikes.co.uk. I will go see Andy about your project.

Don't forget to include pictures, general trike, handlebars, bottom bracket area, where you want the battery.

I was sent an email today from Andy with details of the wheel rebuild, but I'm a little flummoxed as to the absence of a speed sensor. This is something me and the trike owner might need talking through.

"In principle" we are looking to implement the offered solution. I don't know this is going to be a 'one off' because we aren't the only owners looking for this to help elderly riders keep riding, but certainly this would be a 'pilot' for something I'd like to think was a commercial opportunity too, one way or the other.

When the offer of the re-laced BPM motor was initially offered, my first thought was "we" (me and the owner) would make a visit to the store with the trike. At that time, I might use an empty (or full) battery pack to work out where the battery might be located. It's all very well saying it's 'x long' by 'y wide' and 'z deep', it's a much easier job to make decisions with the actual items in front of you, unless you have a 3D modeling suite.... Which I don't. The design target would be to find a way to fit a 20ah x 36v battery underneath the boom. Not using circlips or packing tape, but to have some 'C' shaped hangers machined up, to effectively dangle the battery underneath but still allow the steering arm to move (as shown previously) unhindered beneath the boom.

Being told 'no motors' threw quite a large spanner in that plan. I'm glad to read there is a solution back on the table. I will look out for a 20" x 36 hole wheel rim, that will be suitable for a 2.35 width tyre.

If I don't get in touch tomorrow please don't think I've gone cold on the idea. I've quite a lot of mundane stuff on my hands at the moment, and for the last couple of weeks everyone but me has had priority. For example I went to do a 4 hour stint working in a garden today. I did about 90 minutes outside, then spent close to 4 hours doing I.T. stuff. [On site for 5½ hours.]

Firstly, I was given the wrong password to this chaps router, and he needed the recently upgraded PC to talk to the outside world of course. That took 20 minutes for me to work out the problem. (I had the BT panel from the router given to me, but the wear on it had an "O" that wouldn't work whether it was a capital O, or a zero. Turns out it was actually a "Q".) Then moved on to trying to set up two printers for him......

Initially he had become frustrated when the WiFi function on the printers would not work. How could it, no WiFi transmitter on the PC. So then we tried with a cable, which ended up with me concluding his USB cable was faulty, the response was; "it was working before". After 2 hours of me bashing my head against a brick wall, I had to walk away. Half an hour later, I am told he "took my remarks on board", replaced the cable I told him was faulty, and the first of the two printers whirred into life. The second printer started working when I unplugged some of the equipment he also had plugged into a 5 or 6 port unpowered USB hub. In fact I think the printer cable ended up plugged directly into computer which allowed the PC to then see the printer. Drivers loaded, printer No.2 began working.

Moral of the story? Don't take a rake, a small fork and a sieve to a job when you are going to spend the afternoon doing I.T. And I still have the gardening job to do.

you should trying dealing with ebike shops and shitmano and Madison i want to give you what you want for a ep8 motor and display and all the stuff to upgrade from a e8000 feck off.

can i buy a e8000 and send you the motor,and buy one with 2year warranty nope feck off.

seems Madison only do warranty replacements and after 2 years when warranty ends its time for the tip.

now i can get a ep8 from ebay from Germany but unless i can get a dealer to play ball as need the software to copy the motor angle over it wont even fkn work or have any warranty and cost 900 quid and might not even fit his carbon frame

can i buy a e8000 and send you the motor,and buy one with 2year warranty nope feck off.

seems Madison only do warranty replacements and after 2 years when warranty ends its time for the tip.

now i can get a ep8 from ebay from Germany but unless i can get a dealer to play ball as need the software to copy the motor angle over it wont even fkn work or have any warranty and cost 900 quid and might not even fit his carbon frame

we sold the BPM kits for many years, up until before covid. I was doing Andy's job then. The product is still on our hub kit webpage. It's a powerful and heavy motor, you'll need torque arms if you don't have steel fork. You can see why I say messy compared to the XF07 front hub kits that don't need torque arms.That isn't instilling confidence? The correspondence I have been having with Andy, has never mentioned "bits" of a kit, it's always been 'motor/controller/battery', and I have sent pictures regarding this already.

Besides the motor, the rest of the kit is same compared to the XF07.

You can see the torque arms here:

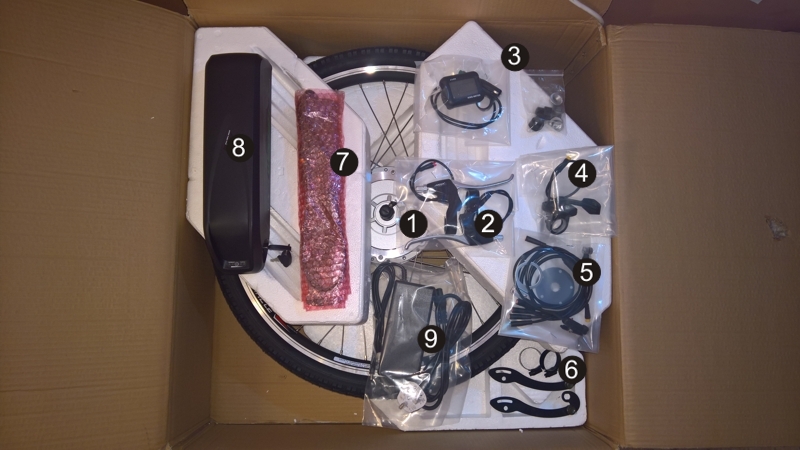

Here is the kit:

Last edited:

Don't worry about the speed sensor, it's just a problem for us, not for you. Andy happened to have a BPM wheel with 3-pin next to him when I went to see him about your project. We did not talk about speed sensor then. Otherwise I would have offered suggestions.I was sent an email today from Andy with details of the wheel rebuild, but I'm a little flummoxed as to the absence of a speed sensor. This is something me and the trike owner might need talking through.

The major issue is whether go for something like the XF07 which is simple to fit or the big heavy BPM motor.

The old BPM kit came with external speed sensor(marked 4) like in the picture above.

The current hub kits all have speed sensor built inside the motors and 9-pin Julet motor cableset. I can supply you a Big Bear wheel that has internal speed sensor or the old set with external speed sensor.

For tadpoles and other trikes like yours, it is usual to fit a battery tray like this:At that time, I might use an empty (or full) battery pack to work out where the battery might be located. It's all very well saying it's 'x long' by 'y wide' and 'z deep', it's a much easier job to make decisions with the actual items in front of you, unless you have a 3D modeling suite.... Which I don't. The design target would be to find a way to fit a 20ah x 36v battery underneath the boom. Not using circlips or packing tape, but to have some 'C' shaped hangers machined up, to effectively dangle the battery underneath but still allow the steering arm to move (as shown previously) unhindered beneath the boom.

It's beginning to look like, as long as owners don't allow the bearing to get so bad the central shaft starts to wear away the PCB, it's now possible to get these motors refurbished by commercial repairers. I have no idea about prices, but the repairs are commercially available.you should trying dealing with ebike shops and shitmano and Madison i want to give you what you want for a ep8 motor and display and all the stuff to upgrade from a e8000 feck off.

can i buy a e8000 and send you the motor,and buy one with 2year warranty nope feck off.

seems Madison only do warranty replacements and after 2 years when warranty ends its time for the tip.

now i can get a ep8 from ebay from Germany but unless i can get a dealer to play ball as need the software to copy the motor angle over it wont even fkn work or have any warranty and cost 900 quid and might not even fit his carbon frame

I'm a bit surprised, the likes of Bafang haven't made a replacement system designed around the Shimano mountings. Or maybe someone has?

I have sent some emails to you directly. You have quite a lot of reading, in your email account.Don't worry about the speed sensor, it's just a problem for us, not for you. Andy happened to have a BPM wheel with 3-pin next to him when I went to see him about your project. We did not talk about speed sensor then. Otherwise I would have offered suggestions.

The major issue is whether go for something like the XF07 which is simple to fit or the big heavy BPM motor.

The old BPM kit came with external speed sensor(marked 4) like in the picture above.

The current hub kits all have speed sensor built inside the motors and 9-pin Julet motor cableset. I can supply you a Big Bear wheel that has internal speed sensor or the old set with external speed sensor.

Thanks for the responses above.

Related Articles

-

MTF Enterprises announces acquisition of EMU Electric Bikes

MTF Enterprises announces acquisition of EMU Electric Bikes- Started by: Pedelecs

-

Wisper 806T folding bike wins Which? ‘Best Buy’

Wisper 806T folding bike wins Which? ‘Best Buy’- Started by: Pedelecs

-

Sustrans calls for protected cycle lanes

Sustrans calls for protected cycle lanes- Started by: Pedelecs

-

Amazon launch their first UK e-cargo micromobility hub

Amazon launch their first UK e-cargo micromobility hub- Started by: Pedelecs