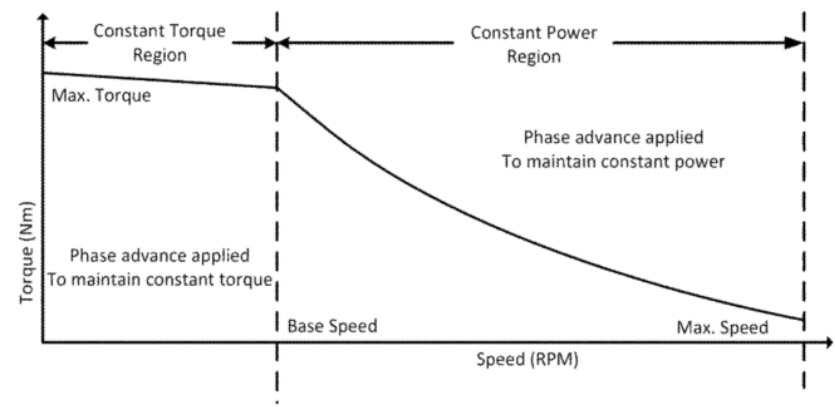

Indeed, my understanding is that OSF supports 'field weakening' to allow a motor to operate at a wider speed range without changing its voltage. Not really looked at the physics of it but it is a real thing. I believe the OSF hybrid mode works really well to give you the benefits of torque sensing at lower cadence and more of PAS at high cadence where it uses field weakening. You kind of get to have your cake and eat it.I'm not one to spin at a high cadence but as I understand it the OEM firmware cuts assistance around 90rpm but the OSF takes it to around 120rpm.

Jbalatutube on YT has a vid demonstrating this.

I'm not particularly good at judging my cadence but looking at my speed, wheel size and gearing, I was comfortable with 90 rpm ( and on my exercise bike it tells me I'm doing 90 to 100 rpm when I'm performing at my optimum efficiency). Unfortunately the motor with stock firmware is delivering little at this cadence - and it felt considerably worse with voltage sag as the battery charge depleted. I found myself needing to drop to high 60s rpm on steeper sections as the battery depleted and this was causing unwanted knee strain. Obviously I can install lower gearing and accept lower speed which is what I will do.

It feels like some really clever folks have worked wonders with osf. It's just a shame that the stock firmware / kit does not deliver this. I have little doubt I will end up flashing the motor in due course, but will leave stock whilst plenty of warranty period left.

And that was my point, the flashing has some risks, requires IT skills (which I fortunately have), voided warranty etc. A factory delivered unit that delivered this would be a big bonus (I know eco cycles supply flashed motors).

C