The bike cleaning/detailing thread had me going over something that I used to very much enjoying carrying out, and actually became very proficient at. The restoration of classic race bikes.

I have always had a very good mechanical understanding, and pulling things down, and re assembling them to an improved standard comes very easily. I sort of fell into bike restoration, after packing in Super Sport 400 and GP250 racing. The circumstances of my quitting weren't very nice, and I decided at the time to walk away from bikes altogether. That was roughly ten years ago, and I haven't ridden one since. The urge and pull to still be around bikes was too great for me, and some how restoring and selling classic race seemed like a natural progression.

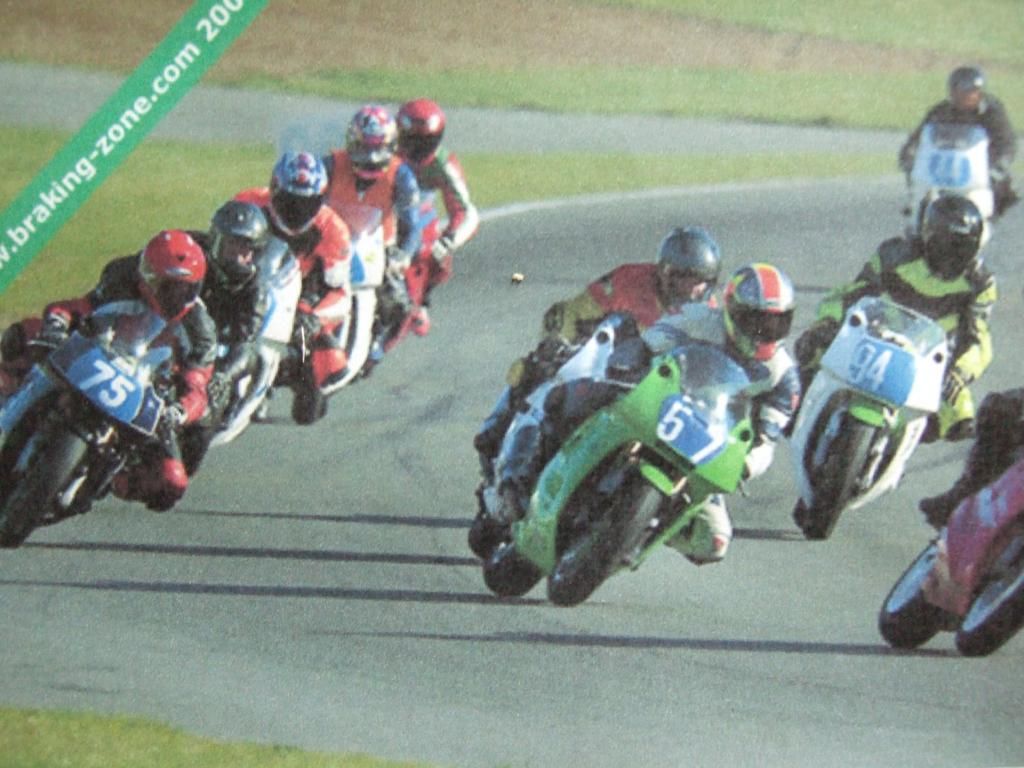

Not in any particular order year are some of the bikes that I have previously restored.

The first shown here, is a very rare Yamaha 3TC1, and after pulling it apart, it sat in boxes for over two years before I could face the restoration. The bike had been badly stored, and corrosion had hit the frame. This corrosion was putting me off, as I knew that it was going to take many hours to hand sand every single mark out, polish the frame to a mirror finish, then carefully sand the metal grain back into the finish, and so making it a flat original finish again. With that horrid job out of the way, the rest is easy. What surprised me was that even after two years, I remember where every single nut and bolt had to go, including thread length, type of washer, and which direction to bolt from. I seem to have an photographic memory for stuff like this, and only glanced at a workshop manual to get the correct torque settings, and lock wire procedure. This bike was actually the last one that I restored. I was putting in too many hours, and not getting the financial reward back from it. Interestingly, when selling the bikes, not one buyer ever came to view. All bikes were sold from photos alone. One went to the IOM, a couple stayed in this country, two went to Italy, one went to France, and one to America. All went into private collections. Sadly the Marlborough coloured 3AK, was smashed up badly at a demonstration event somewhere in France. Prior to that, it had sat in a MC museum close to Paris.

Every single component that can be, is replated to original finish. Sometimes this even means three different colour finishes per bolt, washer and nut. If a bolt is incorrect and a new one can't be purchased with the correct head, I would have the replacement put in a lathe, correctly profiled, then replated again.

And finished. Whilst the engines would always be completely rebuilt, I never once fired any of the bikes up. Doing so would mean that the engine was no longer fresh and rebuilt. It always hurt not doing so, but that is how collectors rightly want them.

I have always had a very good mechanical understanding, and pulling things down, and re assembling them to an improved standard comes very easily. I sort of fell into bike restoration, after packing in Super Sport 400 and GP250 racing. The circumstances of my quitting weren't very nice, and I decided at the time to walk away from bikes altogether. That was roughly ten years ago, and I haven't ridden one since. The urge and pull to still be around bikes was too great for me, and some how restoring and selling classic race seemed like a natural progression.

Not in any particular order year are some of the bikes that I have previously restored.

The first shown here, is a very rare Yamaha 3TC1, and after pulling it apart, it sat in boxes for over two years before I could face the restoration. The bike had been badly stored, and corrosion had hit the frame. This corrosion was putting me off, as I knew that it was going to take many hours to hand sand every single mark out, polish the frame to a mirror finish, then carefully sand the metal grain back into the finish, and so making it a flat original finish again. With that horrid job out of the way, the rest is easy. What surprised me was that even after two years, I remember where every single nut and bolt had to go, including thread length, type of washer, and which direction to bolt from. I seem to have an photographic memory for stuff like this, and only glanced at a workshop manual to get the correct torque settings, and lock wire procedure. This bike was actually the last one that I restored. I was putting in too many hours, and not getting the financial reward back from it. Interestingly, when selling the bikes, not one buyer ever came to view. All bikes were sold from photos alone. One went to the IOM, a couple stayed in this country, two went to Italy, one went to France, and one to America. All went into private collections. Sadly the Marlborough coloured 3AK, was smashed up badly at a demonstration event somewhere in France. Prior to that, it had sat in a MC museum close to Paris.

Every single component that can be, is replated to original finish. Sometimes this even means three different colour finishes per bolt, washer and nut. If a bolt is incorrect and a new one can't be purchased with the correct head, I would have the replacement put in a lathe, correctly profiled, then replated again.

And finished. Whilst the engines would always be completely rebuilt, I never once fired any of the bikes up. Doing so would mean that the engine was no longer fresh and rebuilt. It always hurt not doing so, but that is how collectors rightly want them.