Jerry

I don't qualify as an "expert" wheel builder, but have enjoyed building 700C large diameter wheels for the

Bafang motor on the Torq, and more recently for the hub geared wheels on the back of the Kalkhoffs. I am a big fan of

Roger Musson's techniques, and the wheels have given no trouble !

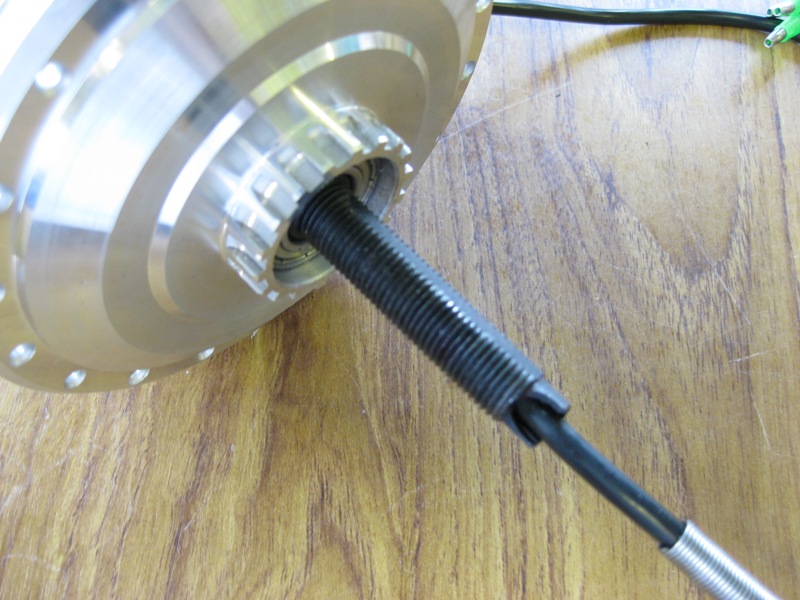

Correctly, you have used a "1 cross" lacing pattern because of the large diameter hub and the small diameter rim (mine have all been large diameter rims like your Cytronex, using a "2 cross" pattern).

With the wide spacing of the hub flanges, personally, I would prefer that the "trailing" (or "pulling") spokes arrive at the inside face of the flanges, giving a straighter pull.

This is not a hard and fast rule, and you will find wheel builders are divided on the subject.

As you begin to even up the tension on the spokes, it is most important to work on the stress relieving of the spokes. Wear leather gloves and "squeeze" pairs of spokes together, such that the 90deg elbows are moving towards 95deg for those on the outside of the flange, and 85deg for those on the inside of the flange.

This aims to make a straight spoke from flange to rim, rather than an arced spoke which is flexing continuously at the elbow.

As you apply more tension to the spokes, you might interrupt the work 4 or 5 times to stress relieve the spokes. Some consider this the most important step.

James