There may be plenty of air flow around the motor but there is none around the windings which is why Statorade etc was developed. You need to shift the heat from the windings to the outside air to keep the motor cool.you can use XF07 to model the XF08C. They are similar enough.

The motor can dissipate 150W OK, there is a considerable laminar flow of air around the motor. On some motors where the emulator has a heat dissipation model like 9Continent 2705 DD motor which in the same condition has a yield of 57% and overheats in 26 minutes. I reckon the XF08C would overheat in roughly 30 minutes, travelling at 10mph, that's a 5 mile long climb.

Waterproofing

- Thread starter Paultr

- Start date

it's just a theoretical risk. 10% gradient climbing at maximum power for 5 miles is 800m vertical, not likely found in the UK.There may be plenty of air flow around the motor but there is none around the windings which is why Statorade etc was developed. You need to shift the heat from the windings to the outside air to keep the motor cool.

Realistically, have you come across any geared hub that died of overheating? Very unlikely. Magnetic fluid has its use but not in ordinary e-bikes otherwise Bosch would have used it for their CX motor.

BTW, DD motors have the same outer rotors like geared hubs, the heat dissipation model on the ebikes.ca is still applicable to geared hubs. ebikes.ca makes a lot of noises about magnetic fluid but all it does is to reduce the temperature of the air between the stator and rotor. When the air temperature reaches equilibrium, the same heat dissipation capacity of the motor stays more or less unchanged. If you change the motor for one with magnetic fluid added, time to overheating is unchanged on their simulator.

Last edited:

I've destroyed 3, all by overheating due to running too much power, although the failure modes were not all the same. I'm positive that none of them would've failed with oil cooling. This of course ignores all the downsides to oil cooling, which I think outweigh the benefits for most people.Realistically, have you come across any geared hub that died of overheating? Very unlikely. Magnetic fluid has its use but not in ordinary e-bikes otherwise Bosch would have used it for their CX motor.

BTW, DD motors have the same outer rotors like geared hubs, the heat dissipation model on the ebikes.ca is still applicable to geared hubs.

Ferrofluid is a totally different matter though. There are virtually no disadvantages to running 5-7ml in a DD hubmotor. As mentioned previously, small quantities of ferrofluid are ineffective in geared motors due to the complex heat path, which is why it is not used by Bosch, or anyone else.

FYI, Grin supplies all DD motors with Ferrofluid installed as standard.

you can always put your theory to test one of these days.I'm positive that none of them would've failed with oil cooling.

The capacity of cooling is down to the design of the motor's casing, not influenced by the added thermal fluid, whether magnetic or not. It's just like your house radiator. You can use circulating water with or without additives, it's not going to change its capacity of heating.

Bosch wouldn't need to use it, their motor is more likely to be spinning at a realistic speed. Air is a very good heat insulator, most home insulation products work by trapping air in a confined space so you will never achieve equilibtium, the windings will always be significantly hotter than the housing.it's just a theoretical risk. 10% gradient climbing at maximum power for 5 miles is 800m vertical, not likely found in the UK.

Realistically, have you come across any geared hub that died of overheating? Very unlikely. Magnetic fluid has its use but not in ordinary e-bikes otherwise Bosch would have used it for their CX motor.

BTW, DD motors have the same outer rotors like geared hubs, the heat dissipation model on the ebikes.ca is still applicable to geared hubs. ebikes.ca makes a lot of noises about magnetic fluid but all it does is to reduce the temperature of the air between the stator and rotor. When the air temperature reaches equilibrium, the same heat dissipation capacity of the motor stays more or less unchanged. If you change the motor for one with magnetic fluid added, time to overheating is unchanged on their simulator.

Btw I'm not advocating the use of ferro fluid or anything else just playing devils advocate because I know I couldn't use a hub motor here. Yesterdays ride had a 5km average 11% climb with an 18% stretch close to the top, I really think a hub motor at 17a with 100w of rider input would struggle up that.

sure. I have the 48V SWX02 kit for that.I really think a hub motor at 17a with 100w of rider input would struggle up that.

same situation with geared hub, with typical 5x reduction ratio. That's why the risk is 5x less than a direct drive motor.Bosch wouldn't need to use it, their motor is more likely to be spinning at a realistic speed.

Apart from on a low power folder, I've all but given up with geared hubs. I wouldn't want to live with the mess of oil bath cooling anyway. Also, the downside of increased drag negates the advantage of them being able to freewheel.you can always put your theory to test one of these days.

Sorry, that's just plain wrong. By far the greatest heat transfer bottleneck is the aigap between the stator and motor shell. Air is a terrible conductor. A coolant just bridges the air gap(s) between the stator and motor casing, improving heat transfer from the windings to the motor shell.The capacity of cooling is down to the design of the motor's casing, not influenced by the added thermal fluid, whether magnetic or not.

The shell to air heat transfer can also be further improved by increasing the surface area of the motor casing through the use of heatsinks.

A better analogy would be to compare running your central heating with or without water. Pumping hot air through a radiator is far less effective versus pumping hot water through it.It's just like your house radiator. You can use circulating water with or without additives, it's not going to change its capacity of heating.

Last edited:

You show a fundamental misunderstanding about the role ferrofluid plays in hubmotor cooling. It's there purely to bridge the gap (displace the air) between the stator and motor casing, allowing faster heat transfer from where the heat is generated.ebikes.ca makes a lot of noises about magnetic fluid but all it does is to reduce the temperature of the air between the stator and rotor. When the air temperature reaches equilibrium, the same heat dissipation capacity of the motor stays more or less unchanged. If you change the motor for one with magnetic fluid added, time to overheating is unchanged on their simulator.

Last edited:

The air inside the motor is not still, it is in a forced convection.Sorry, that's just plain wrong. By far the greatest heat transfer bottleneck is the aigap between the stator and motor shell. Air is a terrible conductor. A coolant just bridges the air gap(s) between the stator and motor casing, improving heat transfer from the windings to the motor shell.

The shell to air heat transfer can also be further improved by increasing the surface area of the motor casing through the use of heatsinks.

For a good approximation, instead of using the still atmospheric air conductance, you need to add the heat transfer due to laminar flow which is 10-100 times more than still air.

Let me give you some numbers to nail that sales pitch for magnetic fluid.

the ferritic fluid will form a film, coating the stator and rotor, with a thickness less than 1mm. It does not bridge the airgap, just reduce the airgap by replacing air with oil. I accept that oil has better thermal conductance than air, but it is less good than steel.

For the sake of argument, let's say you have 5cm of steel in the stator, 2mm airgap, 1cm steel in the stator and shell.

You add 0.5mm of oil (film).

= 6cm steel + 0.2cm air

Your circuit becomes:

5cm steel + 0.05cm oil + 0.1cm air + 0.05cm oil + 1cm steel

= 6cm steel + 0.1cm air + 0.1cm oil

thermal conductance of

still air: 0.0262

steel: 16.3

engine oil: 0.15

If the motor isn't running:

Your thermal resistance becomes:

Before:

=6/16.3 + 0.2/0.0262 = 8

After addition:

=6/16.3 + 0.1/0.0262 + 0.1/0.15 = 4.85

Great, the sales pitch can claim 40% improvement.

If the motor is running at 100rpm:

air speed in the gap: 0.05m * radian * pi * 100 (rpm) * 5 *(reduction ratio) / 60 = 0.033m/s

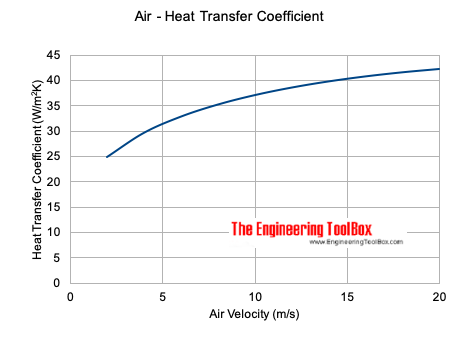

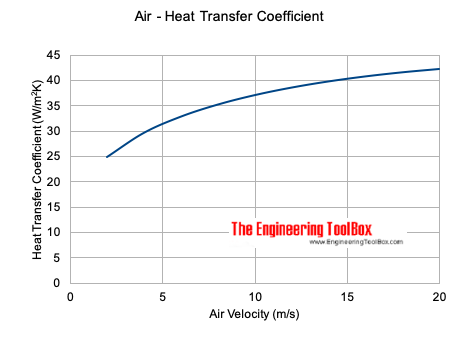

There is a table for air - heat transfer coefficient here:

This is roughly about 5-7 for 3cm/s air flow.

Before:

6cm Steel = 6/16.3 = 0.3681

2mm airgap =0.2 /(0.0262 * 6) = 1.272265

= 6/16.3 + 0.2 /(0.0262 * 6) = 1.64

After addition:

1mm oil: 0.1/0.15

=6/16.3 + 0.1 /(0.0262 * 6) + 0.1/0.15 = 1.67

It can only be a few percents either way, you would lose if the motor spins faster, and if you put in more oil, you would make it slightly worse.

Without even looking at your numbers, there's so much wrong with your general understanding of ferrofluid.The air inside the motor is not still, it is in a forced convection.

For a good approximation, instead of using the still atmospheric air conductance, you need to add the heat transfer due to laminar flow which is 10-100 times more than still air.

Let me give you some numbers to nail that sales pitch for magnetic fluid.

the ferritic fluid will form a film, coating the stator and rotor, with a thickness less than 1mm. It does not bridge the airgap, just reduce the airgap by replacing air with oil. I accept that oil has better thermal conductance than air, but it is less good than steel.

For the sake of argument, let's say you have 5cm of steel in the stator, 2mm airgap, 1cm steel in the stator and shell.

You add 0.5mm of oil (film).

= 6cm steel + 0.2cm air

Your circuit becomes:

5cm steel + 0.05cm oil + 0.1cm air + 0.05cm oil + 1cm steel

= 6cm steel + 0.1cm air + 0.1cm oil

thermal conductance of

still air: 0.0262

steel: 16.3

engine oil: 0.15

If the motor isn't running:

Your thermal resistance becomes:

Before:

=6/16.3 + 0.2/0.0262 = 8

After addition:

=6/16.3 + 0.1/0.0262 + 0.1/0.15 = 4.85

Great, the sales pitch can claim 40% improvement.

If the motor is running at 100rpm:

air speed in the gap: 0.05m * radian * pi * 100 (rpm) * 5 *(reduction ratio) / 60 = 0.033m/s

There is a table for air - heat transfer coefficient here:

This is roughly about 5-7 for 3cm/s air flow.

Before:

6cm Steel = 6/16.3 = 0.3681

2mm airgap =0.2 /(0.0262 * 6) = 1.272265

= 6/16.3 + 0.2 /(0.0262 * 6) = 1.64

After addition:

1mm oil: 0.1/0.15

=6/16.3 + 0.1 /(0.0262 * 6) + 0.1/0.15 = 1.67

It can only be a few percents either way, you would lose if the motor spins faster, and if you put in more oil, you would make it slightly worse.

Firstly, it does bridge the air gap - it is attracted directly to the magnets, that much is plain to see when it's applied. It has been calculated through prior testing and research that 1ml is effective for each 50cm2 of rotor surface area, without increasing drag by a noticeable amount. I can't remember the exact improvement in stator-to-air heat transfer, but I think it's around 100%. Combining with hubsinks yields around a further 60% improvement still, although I've never tried these.

http://www.ebikes.ca/product-info/statorade.html

There is a rather lengthy but detailed thread on the subject of motor cooling here, but it covers far more than just ferrofluid cooling:

https://endless-sphere.com/forums/viewtopic.php?f=2&t=48753

Ignore it at your peril!

Last edited:

no, it doesn't.Firstly, it does bridge the air gap

1ml = 1cm3

1cm3 / 50cm2 = 0.02cm = 0.2mm

Your airgap is about 2mm. 10 times the thickness of the oil film.

You're forgetting that FF is magnetic and therefore forms columns between the stator and magnets. It bridges the air gap enough to have a dramatic effect on cooling. If you want greater bridging, use more FF. This will of course increase motor drag though. Also, FF suitable for this application is not cheap.no, it doesn't.

1ml = 1cm3

1cm3 / 50cm2 = 0.02cm = 0.2mm

Your airgap is about 2mm. 10 times the thickness of the oil film.

You need to read the openly published testing procedures and resulting evidence/data linked to previously. It trumps your theoretical arguments.

Last edited:

This topic should really be discussed elsewhere.

I am not convinced that there is any benefit using ferritic fluid in geared hubs. There are good reasons why people who use DD motors are looking for coolant. Overheating is a real problem for those motors made worse by the low rotor RPM and high Amp so any improvement is worth considering.

I am not convinced that there is any benefit using ferritic fluid in geared hubs. There are good reasons why people who use DD motors are looking for coolant. Overheating is a real problem for those motors made worse by the low rotor RPM and high Amp so any improvement is worth considering.

Having already stated this multiple times, I couldn't agree more.This topic should really be discussed elsewhere.

I am not convinced that there is any benefit using ferritic fluid in geared hubs.

DD motors are so much better suited for hot-rodding and those that do go this route, tend to want to eek out every last bit of performance. This is where FF + hubsinks shine - I think the phrase is "game changer".There are good reasons why people who use DD motors are looking for coolant. Overheating is a real problem for those motors made worse by the low rotor RPM and high Amp so any improvement is worth considering.

The other side of the coin is that FF lets you use a smaller DD motor than would have to be used otherwise.

Last edited:

that DD motors are pantz for 15mph assist jobs and climbing hills.The other side of the coin is

Go troll somebody else.that DD motors are pantz for 15mph assist jobs and climbing hills.

Does actual fact as these additives shift the air out of the water and prevent corrosion. Most effect is a vortex device. http://www.vortexenergysaver.com/.you can always put your theory to test one of these days.

The capacity of cooling is down to the design of the motor's casing, not influenced by the added thermal fluid, whether magnetic or not. It's just like your house radiator. You can use circulating water with or without additives, it's not going to change its capacity of heating.

Air as you know is a great insulator and anything that does remove air aids cooling. Air can also carry moisture and assist in oxidation of certain metals.

Still no oil leakage and I increased the battery to 40Ah.

That electrical contact spray and water repellent may have saved one of my rear lights. Few heavy showers -akin bucket of water falling- and one the switch obvious shorted. The battery compartment was wet and after a few sprays all is good. Also opened up the SW900 and soaked it in contact spray. Time will tell.

Last edited:

Related Articles

-

Swytch announce new conversion kit with ‘pocket-sized’ battery

Swytch announce new conversion kit with ‘pocket-sized’ battery- Started by: Pedelecs

-

New Swytch launches on Indiegogo, raises £100k in first hour

New Swytch launches on Indiegogo, raises £100k in first hour- Started by: Pedelecs

-

Swytch to unveil 70% smaller, 50% lighter conversion kit

Swytch to unveil 70% smaller, 50% lighter conversion kit- Started by: Pedelecs