finaly to the bad things:

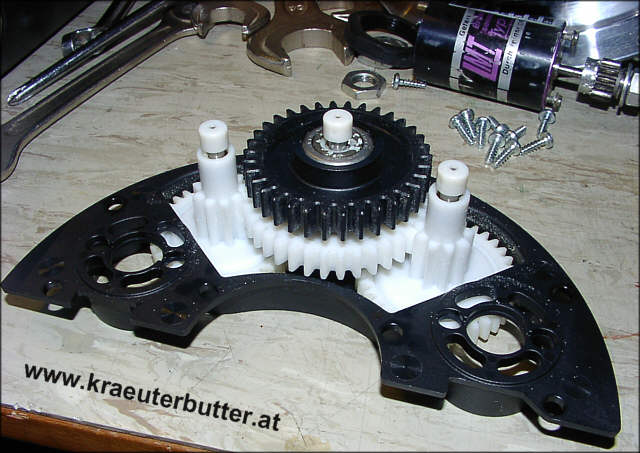

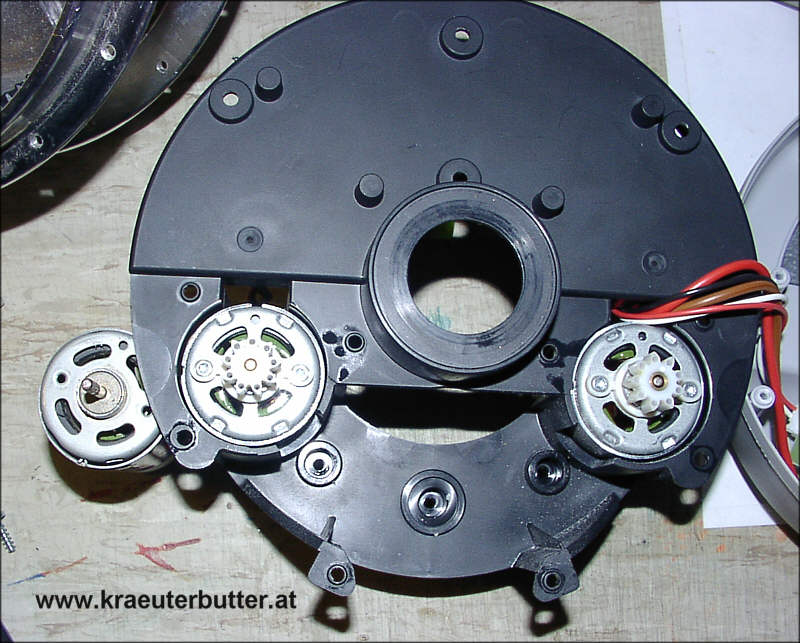

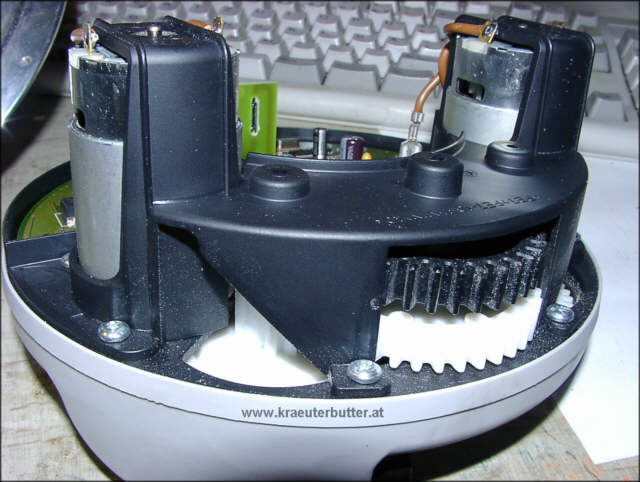

the plastic used inside the sparc is realy of cheap make !!!

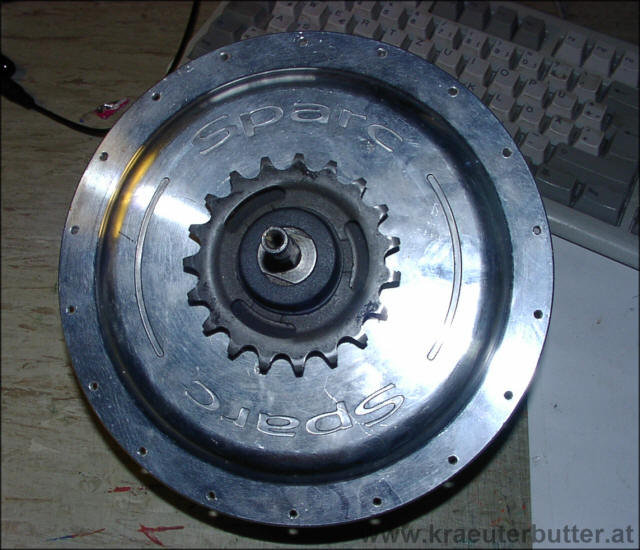

i realy don´t know why the sparc is that expensive

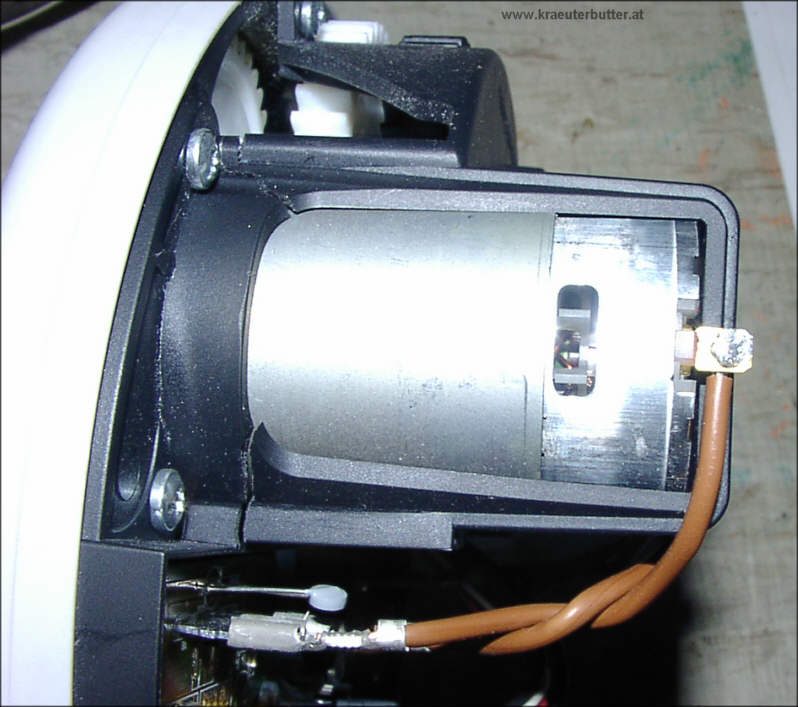

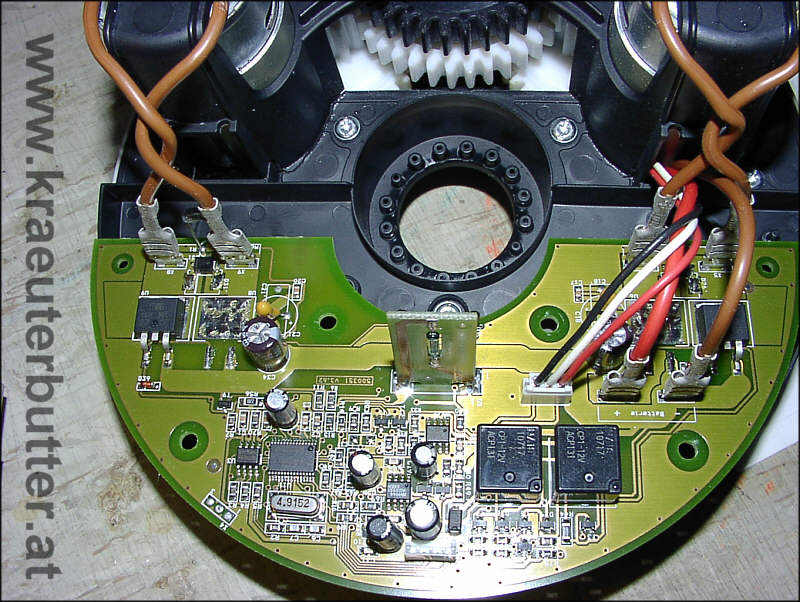

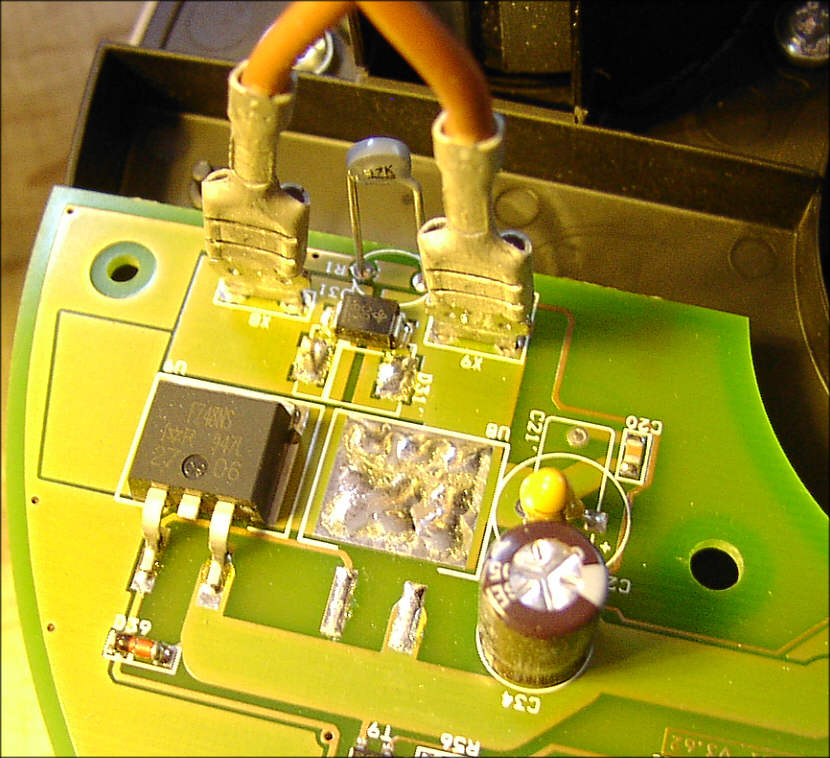

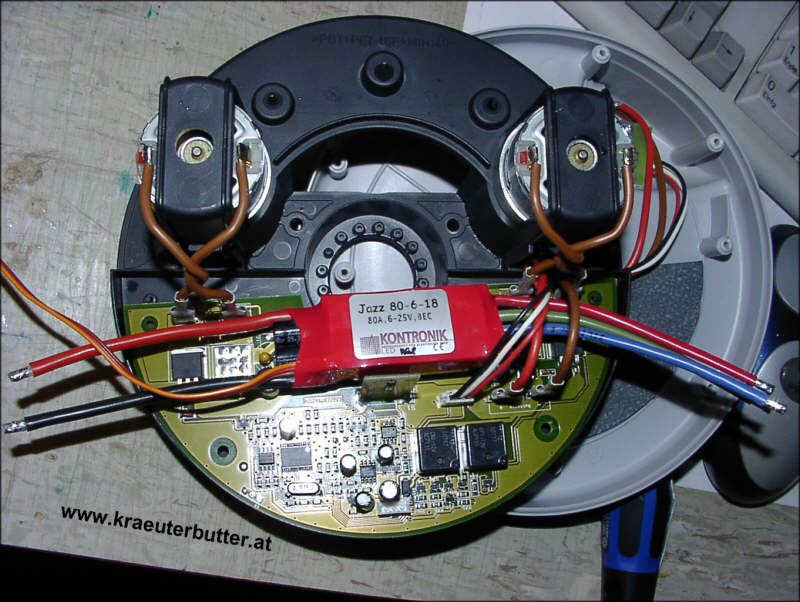

(cheapest motors, cheap controller/electronics, poorest plastics)

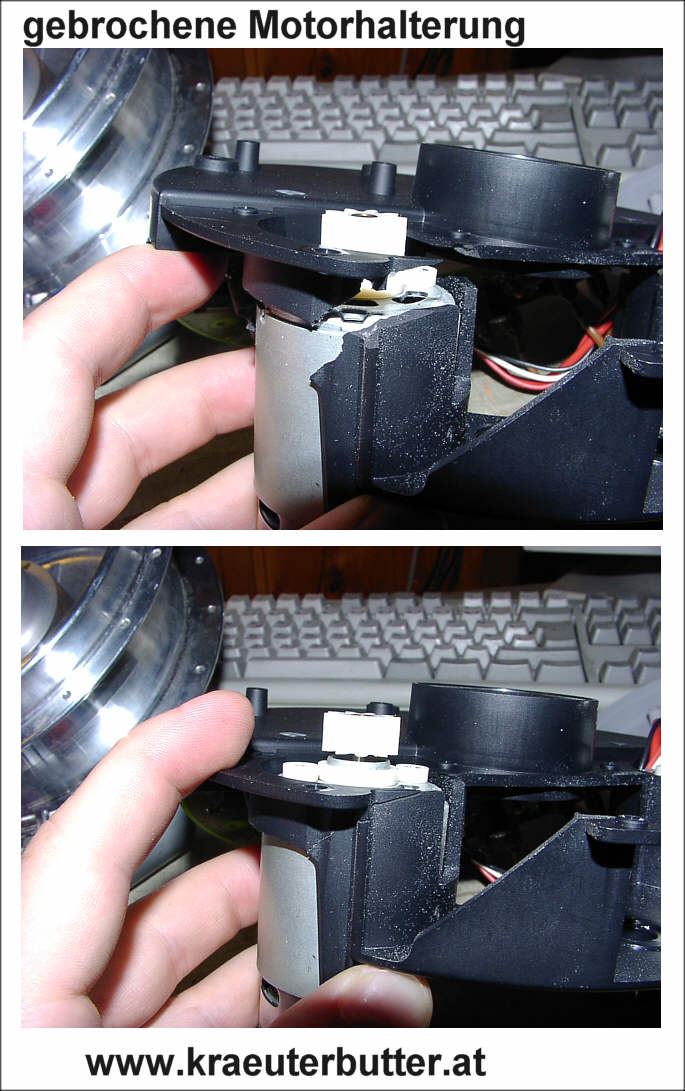

even on the cheapest rc-cars (more toys than cars) the plastic is more robust than this inside the sparc which helds the motors:

effect:

the motor-holding plastic-parts are broken !

its broken on a wide range, i think 70% of the material that holds down the motors is broken of the ground-plate !!

i don´t think that this comes from the little torque the motors provide..

its - like on rc-cars - from g-forces..

(when jumping a car 0.5m high and landing, the weight of the motor has to be absorbed by the motormount.. a cheap plastic-motormount can break on this..

instead: a high-quality carbon-kevlar-improved plastic will survive landings from 3-5m hights !)

so i think, the bike with the sparc mounted was going over curbstones by the previouse owner..

this was enough, so that the ~220g heavy motors cracked the motor-mount..

here would be a part made from higher quality plastic (improved by carbon-fabrics/fibers like on rc-car-chassis) very nessessary...

question is:

will i get a replacement part (maybe worth 5 US$) by SRam, or will they want me to send in the sparc to replace it ?

(that would cost me all together (sending to Germany, sending back, price for repair) maybe 100US$

before i send in all the parts, i will try to fix it myself with carbon-fibres, CA and or epoxyd-glue

combined with fine cotton streak

so..

first conclusion when looking to the dismanteld things:

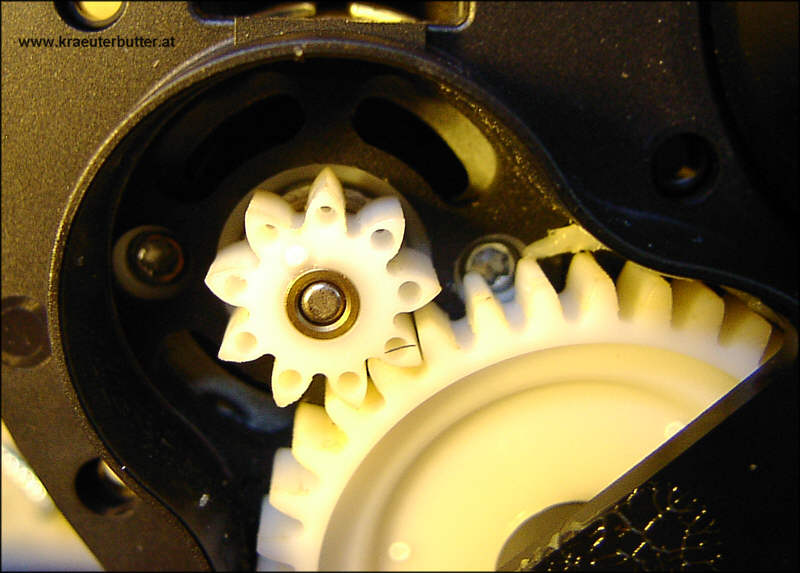

i think the gears look very rigid.. should not fail

the mounting of the gear-shafts seems also to be rigid enough that tourque does not kill there anything

a big problem is the weak plastic, that can not support the weight of the motors (g-forces when driving on a not that clean road which causes agitation makes the plastic break under the load of the little 220g motors !)

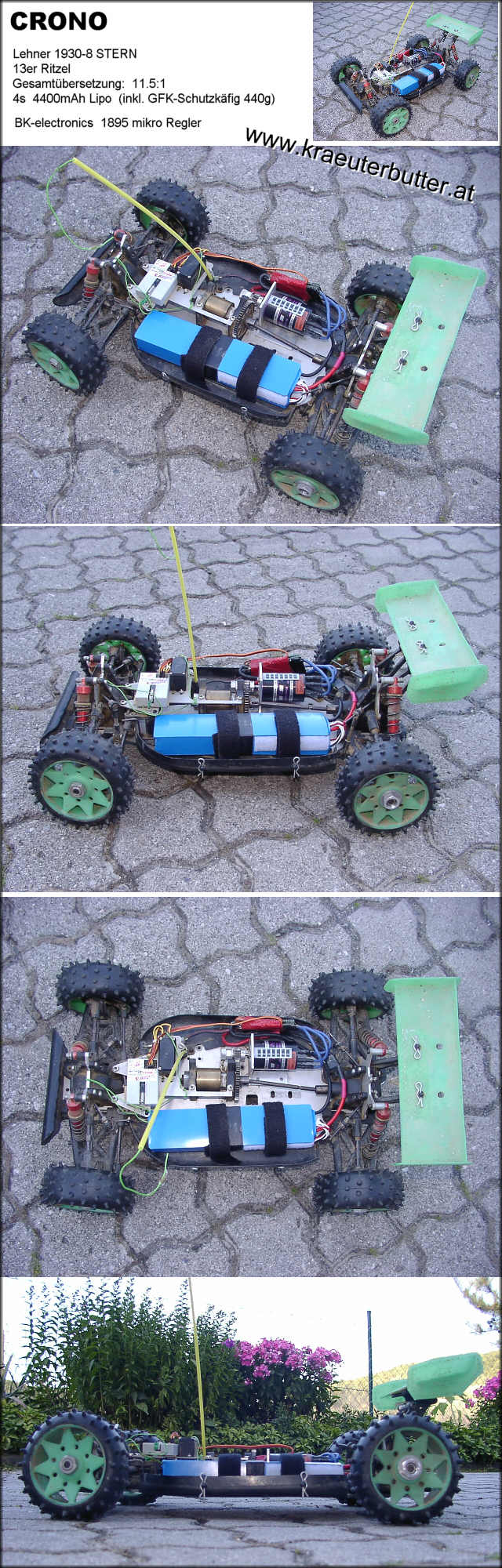

the motors + gears + electronics + cap weights only 837g

(the motors themselfs: 220g each)

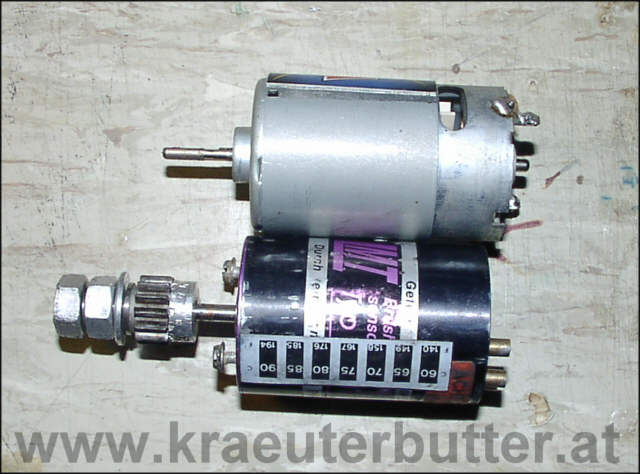

for the Lehner-MOtor:

mounting itself should not be a problem (same mounting holes, same diameter, same length)

Problem maybe to find a suitable pinion for the motor, because the lehner has a 4mm shaft

(a 3.17mm shaft like the sparc-motors would break at peak-powers of ~2000Watt what this motor is able to handle)

another thing: i wonder why there are nowere ball-bearings used...

on such an expensive part i thought ballbearings should be standard..

next steps:

* repairing of the plastic

* mount it on the bike..

* first testruns with desition if i need and want to modify it with stronger, brushless motor

Flecc: mounting only one motor would not be a problem at all, as said: no belt