Hi guys,

New here and after getting some excellent advice here recently I wanted to ask the boffins a theoretical technical question. I recently borrowed a spot welder from a mate who bought it on ebay for the same reason, making our own batteries. He could only get it to run at work as the current draw is too much for normal house circuits, he failed (or forgot) to mention this when he dropped it off.

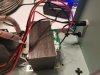

It’s a cheapo Sunko 788h which I had a little dig around being curious. I have limited experience with electronics but do have good soldering skills having worked in a factory as a youngster tinning and soldering capacitors and transistors on a production line and I had a thought.

I’ve already given up on the idea of putting my own pack together and have been talking to Jimmy at Insat to arrange for him to make the battery using my own sammy 30q cells and then I got wondering whether the transformer in this machine which I presume is what’s causing the huge initial current pull and subsequent breaker trip to happen could be replaced with a car battery, i.e. keep the main circuits powered from mains but the actual weld current supplied from the battery, my battery will still be going to Jimmy but was wondering whether this is even possible, maybe even to use on future projects.

I’m only asking as really butthurt over not being able to make my own pack so once that’s sorted maybe a future project.

Thanks

Jonny

New here and after getting some excellent advice here recently I wanted to ask the boffins a theoretical technical question. I recently borrowed a spot welder from a mate who bought it on ebay for the same reason, making our own batteries. He could only get it to run at work as the current draw is too much for normal house circuits, he failed (or forgot) to mention this when he dropped it off.

It’s a cheapo Sunko 788h which I had a little dig around being curious. I have limited experience with electronics but do have good soldering skills having worked in a factory as a youngster tinning and soldering capacitors and transistors on a production line and I had a thought.

I’ve already given up on the idea of putting my own pack together and have been talking to Jimmy at Insat to arrange for him to make the battery using my own sammy 30q cells and then I got wondering whether the transformer in this machine which I presume is what’s causing the huge initial current pull and subsequent breaker trip to happen could be replaced with a car battery, i.e. keep the main circuits powered from mains but the actual weld current supplied from the battery, my battery will still be going to Jimmy but was wondering whether this is even possible, maybe even to use on future projects.

I’m only asking as really butthurt over not being able to make my own pack so once that’s sorted maybe a future project.

Thanks

Jonny

Attachments

-

270.1 KB Views: 32

-

273.1 KB Views: 30

-

300.4 KB Views: 30

-

313.4 KB Views: 28

-

290.7 KB Views: 27

-

294.9 KB Views: 26