People with rear hub motors put a torque arm (or two) on their dropouts to help relieve the stress caused by the hub motor, but when you have got rear suspension and the motor applies power, is this not also making your rear triangle move upwards slightly? Think about it, the wheel rotates clockwise (from the drive side), now imagine you had super powers and could grab that wheel and stop it from being powered - won't the rear triangle of the frame put a bit of pressure on the rear shock?

What I am getting at is, on a rear suspension frame with a rear hub motor, isn't the suspension itself acting as a torque arm? The motor does rotate the wheel under load in such a way that I think it might be doing.

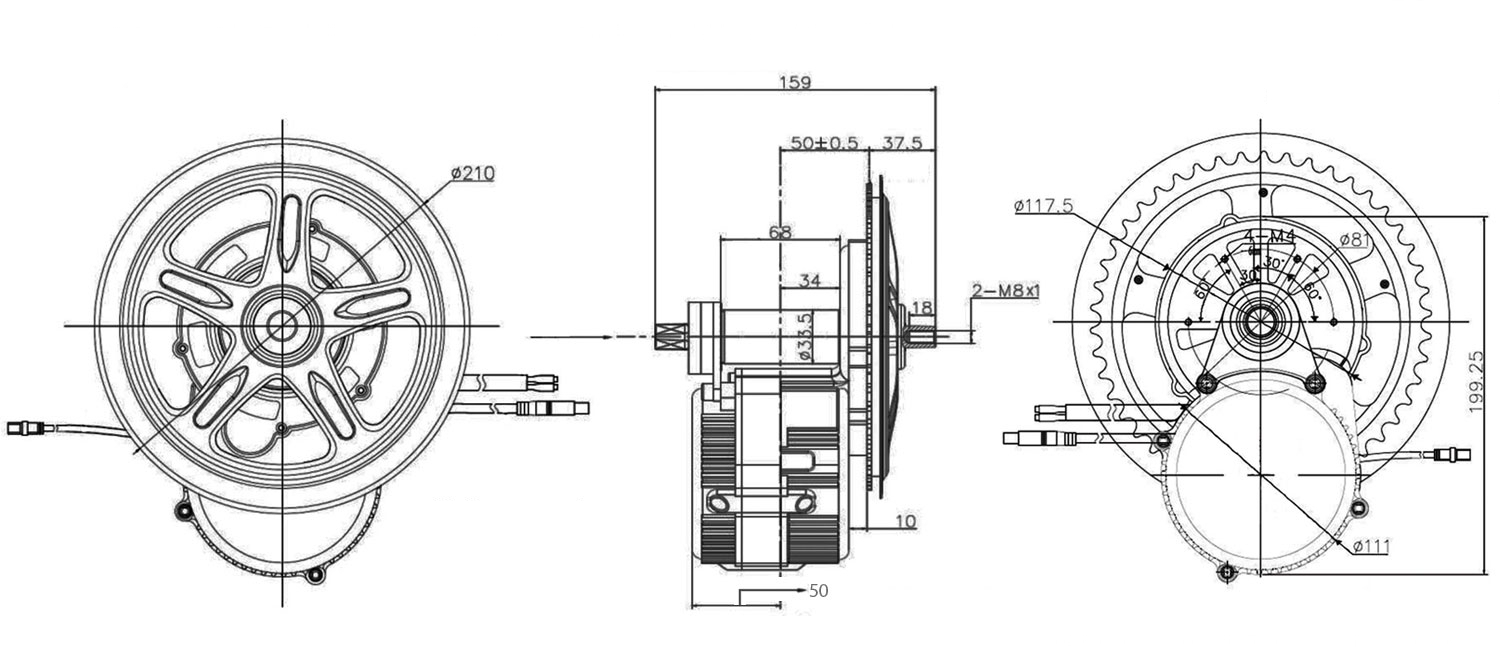

Also, if you have a rear motor that puts out say 45Nm, like the 500W Bafang does, but you tightened each wheel nut to 40Nm each, you then have 80Nm of force holding your rear wheel on - so what's the point of a torque arm in that situation when your motor is 35Nm under the force required to loosen the nuts at the dropouts?

All very interesting isn't it.

What I am getting at is, on a rear suspension frame with a rear hub motor, isn't the suspension itself acting as a torque arm? The motor does rotate the wheel under load in such a way that I think it might be doing.

Also, if you have a rear motor that puts out say 45Nm, like the 500W Bafang does, but you tightened each wheel nut to 40Nm each, you then have 80Nm of force holding your rear wheel on - so what's the point of a torque arm in that situation when your motor is 35Nm under the force required to loosen the nuts at the dropouts?

All very interesting isn't it.