Currently fitting a MXUS XF08C kit from Woosh.

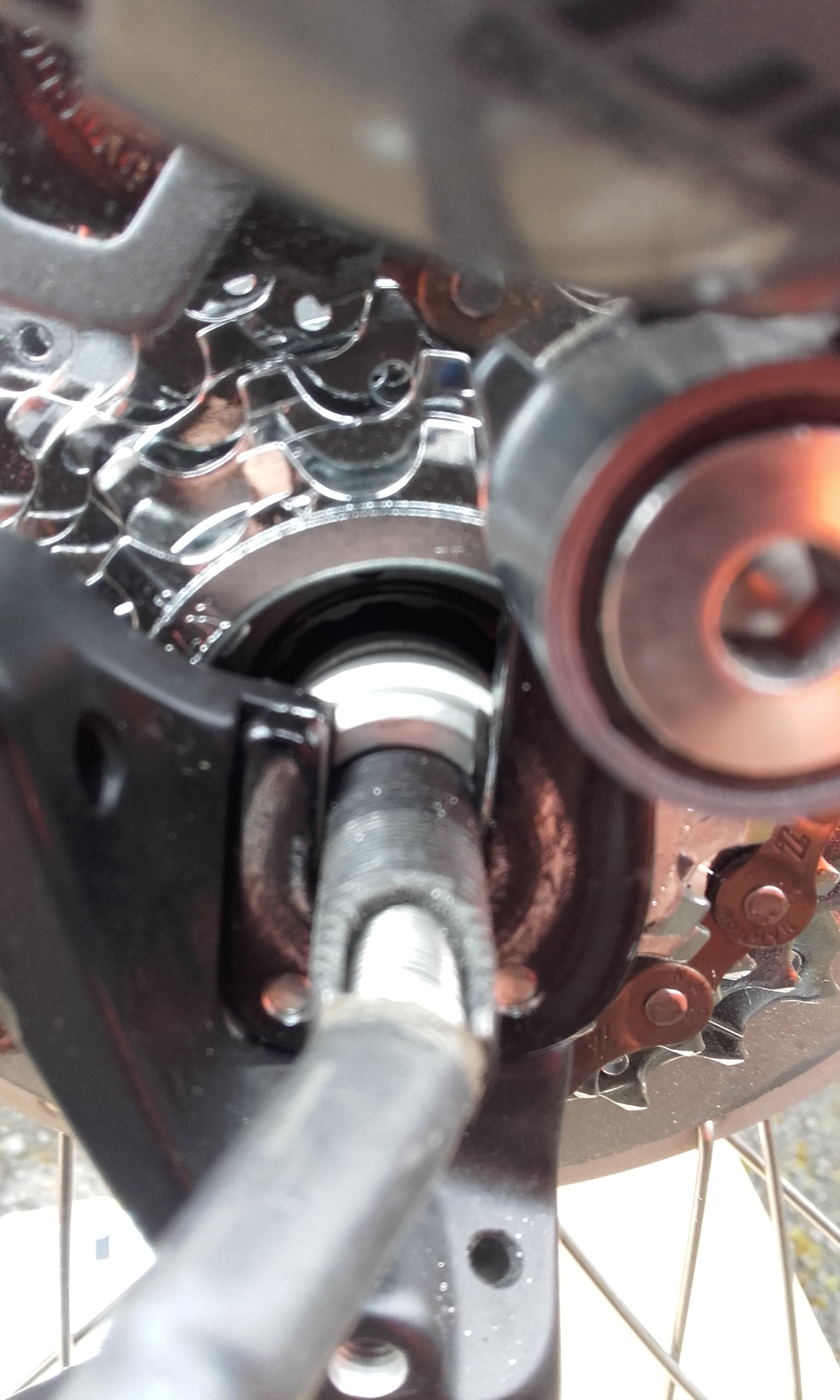

Ran into problems immediately which seems normal. I need to buy a grind tool for my drill today so I can make the dropouts deeper as it does not sit deep enough currently. The disc does still skim the disk pad slightly so may need to do something with that too.

I am waiting for delivery of some riv nuts as will need to fit 2 of em. Shame these are not included in the kit since you nearly always need some. Also waiting for some torque arms just for piece of mind really.

I had to buy some Hydraulic brake sensors elsewhere as woosh does not supply them in the kit or as an option. Got them from here in UK with quick delivery - http://wing-ebikes.co.uk/?page_id=3002

Another problem is there is not enough room for the left brake sensor and the crank arm will squash/crack it so I either need to grind some off the inside of the left crank arm or get a longer spindle bottom bracket.

I am not sure if I get a longer BB if the chain rings will be out of line with the cassette to gain a longer left side? Can you get them with a longer left side only? Or will it be ok just grinding around 5mm of the arm?

I think the 3 hour time guide is a bit off unless you do one a week and know what to expect and instructions should mention grinding dropouts etc too as its not something most people will be fitting often or before even if you are competent etc. Its probably gonna take me more like 12 hours lol.

Ran into problems immediately which seems normal. I need to buy a grind tool for my drill today so I can make the dropouts deeper as it does not sit deep enough currently. The disc does still skim the disk pad slightly so may need to do something with that too.

I am waiting for delivery of some riv nuts as will need to fit 2 of em. Shame these are not included in the kit since you nearly always need some. Also waiting for some torque arms just for piece of mind really.

I had to buy some Hydraulic brake sensors elsewhere as woosh does not supply them in the kit or as an option. Got them from here in UK with quick delivery - http://wing-ebikes.co.uk/?page_id=3002

Another problem is there is not enough room for the left brake sensor and the crank arm will squash/crack it so I either need to grind some off the inside of the left crank arm or get a longer spindle bottom bracket.

I am not sure if I get a longer BB if the chain rings will be out of line with the cassette to gain a longer left side? Can you get them with a longer left side only? Or will it be ok just grinding around 5mm of the arm?

I think the 3 hour time guide is a bit off unless you do one a week and know what to expect and instructions should mention grinding dropouts etc too as its not something most people will be fitting often or before even if you are competent etc. Its probably gonna take me more like 12 hours lol.