I hit a dead end planning to fit my Hollowtech 2 PAS sensor to a carbon MTB frame that has a PF30 bottom bracket shell.

This frame has a Praxis Works Shimano based bottom bracket and while that Praxis thing works really well under normal usage, it is too wide for the PAS sensor ring to fit around it.

It would require a PAS sensor ring that's got an ID of 42.1mm (the Praxis is 42mm).

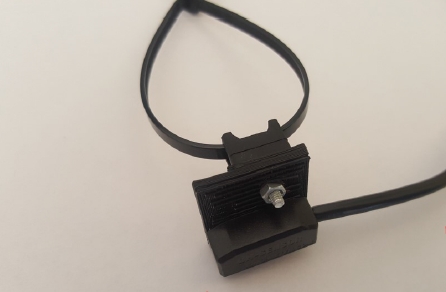

My PAS sensor ring is designed for a standard Hollowtech 2 bottom bracket cup, that's got a diameter of 35mm. My PAS sensor ring is 35.1mm.

This means the PAS sensor ring is 7mm too small on the inside, so it would need 3.5mm filing off around it, leaving it just 1.5mm thick around the edge!

Even if the PAS sensor ring was filed down, it's leaving hardly any material left to it and I'm not sure it would be feasible due to my BB shell bulging out as much as it does.

Praxis Works BB cup: 42 mm

PAS sensor ring: 32.1 mm

PAS ring width: 5 mm

I am sure the Chinese don't make PF30 specific PAS sensors?

This is going to rule out using this frame for me and I'd have to go with my original plan - buy an old aluminium hardtail MTB frame that has a normal 35mm wide BB shell with an IS mount at the rear brake. I spent 2 days sawing, drilling and filing metal plates to use as torque arms on this carbon frame all to find out the sodding PAS can't be fitted!

I have got a throttle on it, but never use it because the PAS is so much more convenient.

This frame has a Praxis Works Shimano based bottom bracket and while that Praxis thing works really well under normal usage, it is too wide for the PAS sensor ring to fit around it.

It would require a PAS sensor ring that's got an ID of 42.1mm (the Praxis is 42mm).

My PAS sensor ring is designed for a standard Hollowtech 2 bottom bracket cup, that's got a diameter of 35mm. My PAS sensor ring is 35.1mm.

This means the PAS sensor ring is 7mm too small on the inside, so it would need 3.5mm filing off around it, leaving it just 1.5mm thick around the edge!

Even if the PAS sensor ring was filed down, it's leaving hardly any material left to it and I'm not sure it would be feasible due to my BB shell bulging out as much as it does.

Praxis Works BB cup: 42 mm

PAS sensor ring: 32.1 mm

PAS ring width: 5 mm

I am sure the Chinese don't make PF30 specific PAS sensors?

This is going to rule out using this frame for me and I'd have to go with my original plan - buy an old aluminium hardtail MTB frame that has a normal 35mm wide BB shell with an IS mount at the rear brake. I spent 2 days sawing, drilling and filing metal plates to use as torque arms on this carbon frame all to find out the sodding PAS can't be fitted!

I have got a throttle on it, but never use it because the PAS is so much more convenient.