ah, thank you for that d8veh, photo's very much appreciated. So please bear with me as am a total newbie. It looks like I have 8x 'good' cell groups (good as in they are 4.2v per group though no idea if they can take a current draw) and 2x u/s groups (which are already way under voltage). So if 2x groups wiped out immediately under a current demand, that would still leave me with 8x 4.2v (33.6v) going into the controller. I gather my controller actions cut-out at 31.5v so the bike should still operate, though we are on the very fine line of ordinary voltage drop under load of the 8x good cells triggering the cut-off? Though having said that, the other day i measured overall voltage output after cut-off at 17v for the whole battery. So is there a chance even the 'good' 4.2v cell groups are worn out also?

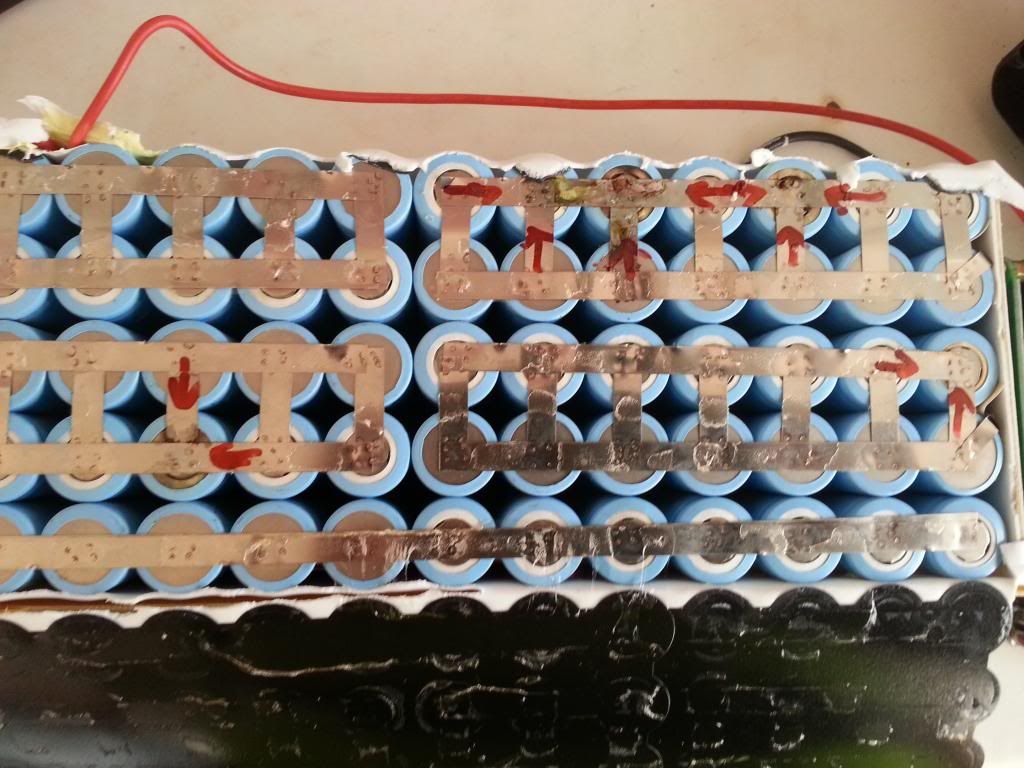

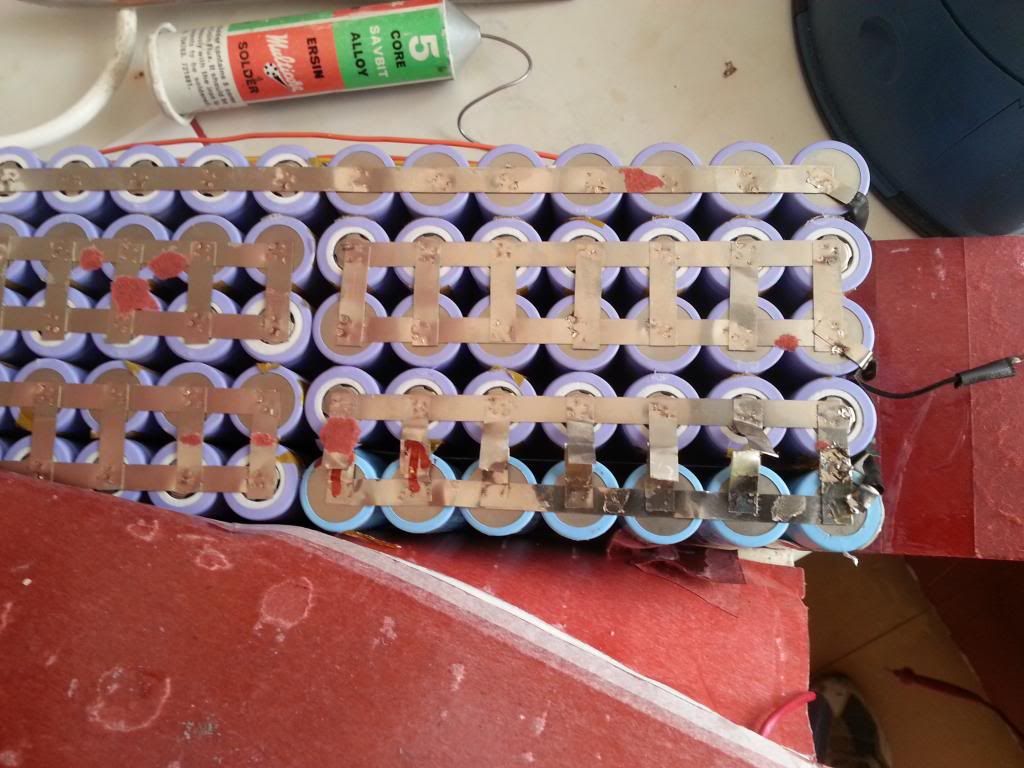

My pack could very well be just like the ones in your pics and I suspect there is a leak also which would explain the low reading from 2x cell groups. Anyones guess at the moment how many individual cells are u/s as the photo shows in your example 14 individual cells per 'unit'. So it could be from 2x to 28x cells gone.

I didn't measure the actual battery pack itself though the inside measurements of the battery casing are 97mm x 88mm (the length of the battery pack itself is about 260mm including the BMS on top, so the battery will be about 220mm in length and is 36v 14ah). Take about 6mm off each of those width & depth measurements for external foam packing (between inside of case and pack), then remove say 3mm for the tape wrapped around the battery pack/any sheet material keeping the cells in place and that would make the actually cell pack measurements 88mm x 79mm...is the height of the cells in the pics anything like either of those measurements?

If it is like above, sadly I do not have any surplus cells to replace the malfunctioning ones with and as much as I am maybe capable of soldering the cut individual battery connectors as you show above am not sure i would wish to as am a bit cack-handed at times!

I also do not have any of the diagnostic equipment that might be required to kick-start individual cell groups.

Even though this is Lithium Polymer battery which I gather has a good service life, I know the battery has been used hard (long hilly journeys) and the pack is now 3 to 4yrs old. Do you think it is worth repairing? Am in no hurry to spend £200 on a new pack though to repair this one I would need a kind soul like yourself to do the repair which means covering the cost of replacement cells and labour inputted. Then there is posting the battery there and back so the costs will soon add up

I really like to recycle when at all possible, but it has to be cost effective and the end result be worthwhile.

It feels a bit debatable on whether it is worth trying to repair?