Another drive failure in my spare bbs01b (motor #2). This motor was installed exactly as received from an aliexpress supplier, with no mods done other than applying mobilgrease 28 to the large gear.

Following stripdown the following was observed:

1.

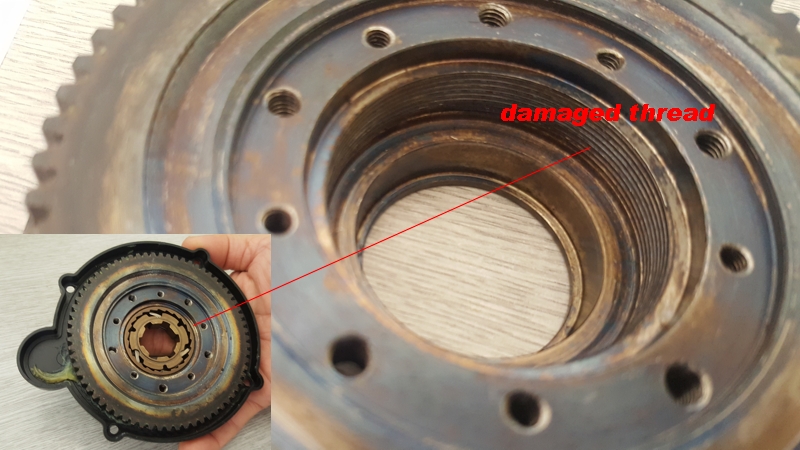

Splines damaged at two positions, one area shown below at 12 o clock. The rest of the splines are in a sorry state after only 1500miles

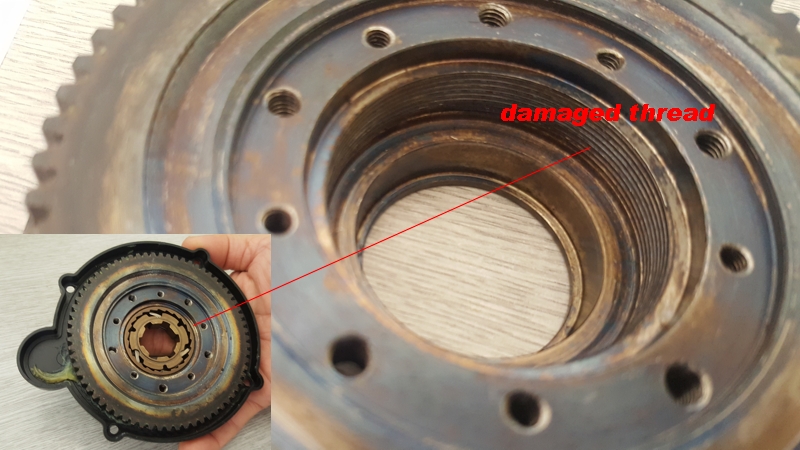

2. Pawl retaining ring had rotated on the pawl carrier. The indent feature had failed to stop rotation of the ring. I was able to reinstate a suitable indent by peening over with a screwdriver. The ring gap had also opened up during running - see picture below (old pawl carrier on left, new unused carrier on right)

3. Pawl wear was minimal when comparing against new unused pawls.

Unfortunately, unlike my experience on motor #1 earlier this year, I was unable to upgrade to the dt-swiss onyx pawls as they wouldn't work on this motor #2. The approach angle of pawl to spline was too shallow leading to occasional drive slippage. I have a new OEM pawl assembly which seems to operates ok though. I will rebuild with a tiny blob.of grease at each pawl pivot, along with a smear of engine oil over the splines.

My mistake - once I'd put the onyx pawls in the right way around, they worked perfectly

Good news is I have enough spares to get up & running again, but am unsure why I'm experiencing such problems. I wonder if my SPD pedals are transmitting too much human torque through the pawls? I'm running a 52t front sprocket with 11-32 at the back, and maintain a cadence of 70rpm to match the motors sweet spot.

Best theory at the moment is the failure of the pawl spring retaining ring feature being the root cause - easily resolved by peening over with a screwdriver & hammer