I'm after a bit of help. I need to calculate spoke lengths but am unsure what to put into the online calculators.

I have a bafang bfswx02 36v 250w motor and a 26" Powercircle rim.

Sorry if this should be obvious. I've done plenty of searching online but managed to tie myself up in knots.

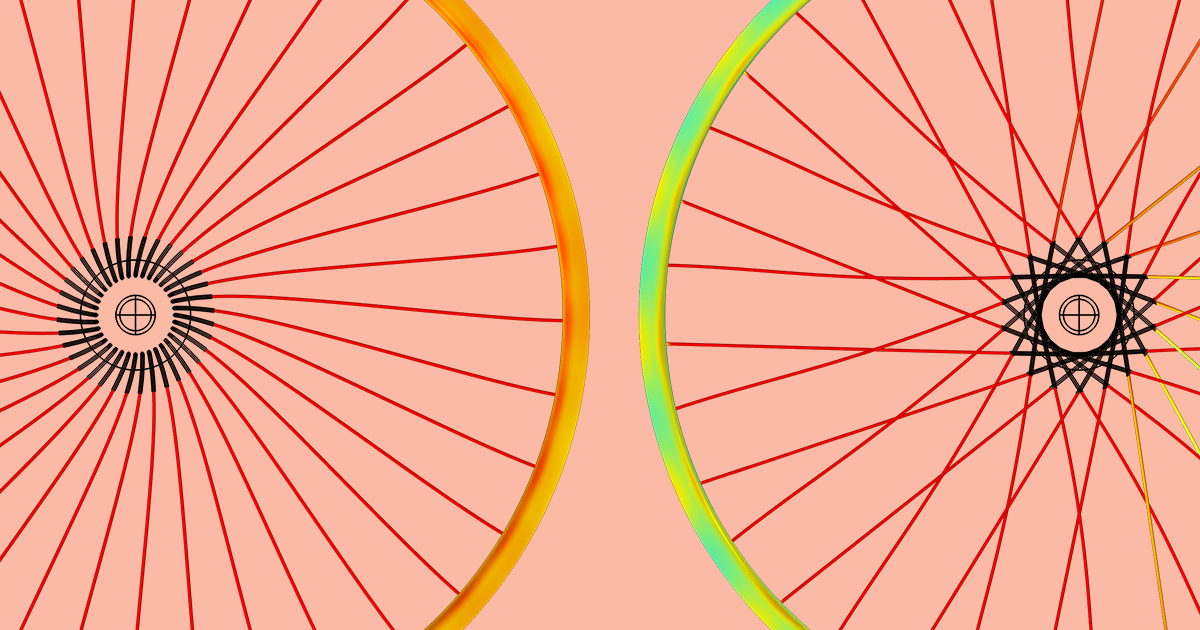

You measure the distance between the two spoke flanges on the motor. Next, you measure the pitch circle diameter of the holes in one flange. You can so that with a piece of stiff cardboard, two nails and some tape. Cut a chunk out of the cardboard to clear anything on the side of the motor, then tape the nails in position while their in diametrically opposite holes. Remove and measure the distance between the nail points with a ruler. If you cut the cardboard right, you can even use a pencil to mark the centre of the holes.

The next thing you need is the rim's ERD, which they sometimes mention in listing, otherwise measure the inside diameter of the rim in two or three places and take the average, then add on 4 or 5mm.

Don't worry about any of the other measurements, though they normally ask for the distance from the centre of the motor/axle to each spoke flange. You can ignore that. Divide the distance between them by two and use that.

Most hub-motors have the centre of the axle off-set from the centre, which means that, in the ideal world, one spoke would be 0.5mm shorter than your calculation and the other 0.5mm longer, but it's not critical, so it's more convenient to get them both the same length (0.5mm longer). Whatever calculation you make, bear that in mind as you round up the calculation to the next whole number. When you have MTB double wall rims, you can go much longer on the spokes than any calculation says, so don't worry about rounding stuff up a couple of mm to the size that the seller has in stock.