Li-ion battery testing

- Thread starter Thakery

- Start date

You can connect a dummy load via a wattmeter which, from a fully charged battery, will tell you exactly what capacity remains relative to new - a simple DIY project which other threads here cover.

If that's beyond your capability, many dealers can do that for you (at a cost).

Ultimately, it's about how many miles the battery can still cover relative to how many miles you could do when the bike/battery was new. So long as the battery still lasts for as many miles as you currently cycle on your outings, then that's fine. Just because the battery is old is nothing to worry about, provided it still has enough capacity for the rides you do. If it doesn't, then a re-cell or new battery would be needed.

Any Kalkhoff dealer should be able to source a replacement battery if your battery version is still made: Store Locator (kalkhoff-bikes.com)

If that's beyond your capability, many dealers can do that for you (at a cost).

Ultimately, it's about how many miles the battery can still cover relative to how many miles you could do when the bike/battery was new. So long as the battery still lasts for as many miles as you currently cycle on your outings, then that's fine. Just because the battery is old is nothing to worry about, provided it still has enough capacity for the rides you do. If it doesn't, then a re-cell or new battery would be needed.

Any Kalkhoff dealer should be able to source a replacement battery if your battery version is still made: Store Locator (kalkhoff-bikes.com)

Last edited:

On Phylion batteries, that test simply shows a representative percentage of how many charge cycles the battery has undergone based on an ideological figure (500/800 cycles to 80% capacity retention): It isn't a measured calculation or true representation of how much capacity the cells actually retain, which after 9 years might deviate substantially from that algorithm/assumption based purely on charge cycles?Your battery, made by BMZ for Kalkhoff, already has a capacity meter built into the charge state button circuit. After fully charging the battery, hold the button down for more than ten seconds for it to show the capacity on the five LED indicator.

.

Kalkhoffs batteries may work differently (I don't know) but I'd guess it's equally as crude. That the OP is asking suggests there's some concern regarding true capacity. IMHO, there's no substitute for actually measuring remaining capacity, which (for most) isn't too difficult with a bit of DIY and a few cheap parts (cheap relative to paying a bike shop to do it for you).

Is that really the current capacity of the battery relative to its capacity when new,Your battery, made by BMZ for Kalkhoff, already has a capacity meter built into the charge state button circuit. After fully charging the battery, hold the button down for more than ten seconds for it to show the capacity on the five LED indicator.

.

or is it just an indication of how much of the current capacity the charge has reached?

If the first that's great; does it also apply to Bosch batteries?

Yes.Is that really the current capacity of the battery relative to its capacity when new,

A normal brief press shows the state of charge.

A sustained press of over 10 seconds displays the capacity.

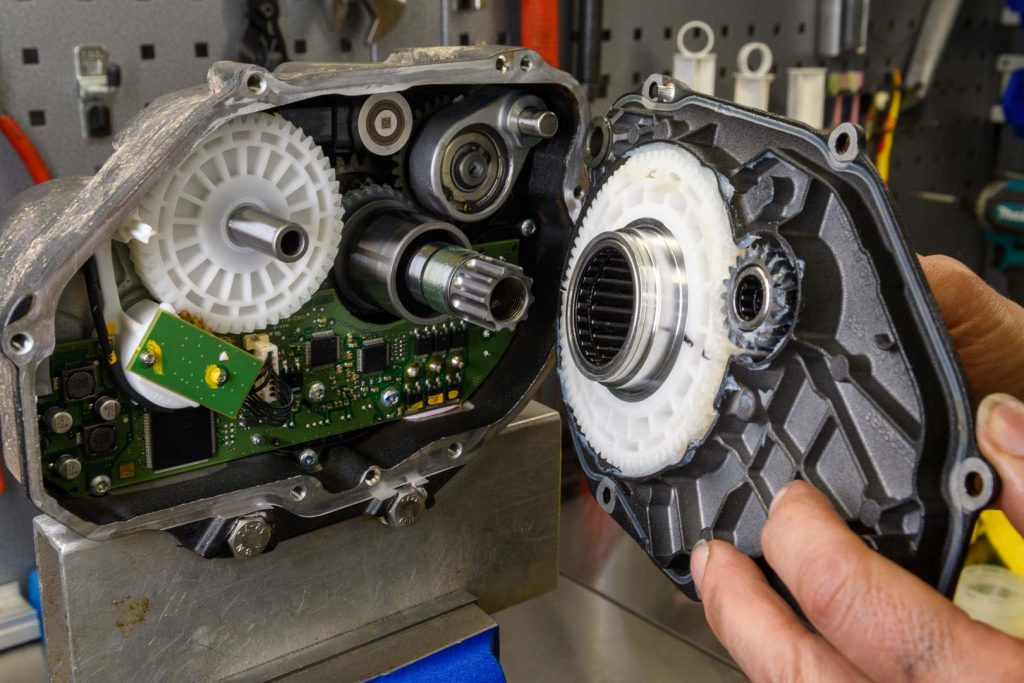

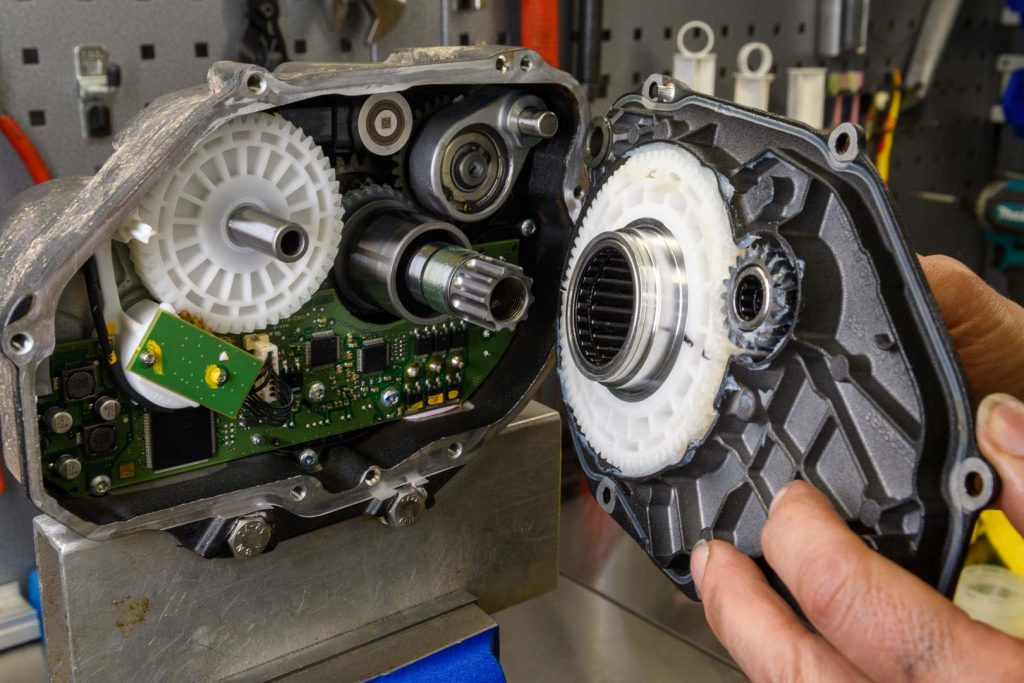

BMZ are a long established German battery manufacturer. They used to make all the batteries for BionX. A Kalkhoff battery innards below:

I don't know if the Bosch batteries have this feature.

.

Certainly on Bosch batteries, from what I've seen, the normal dealer software shows charge/discharge cycle count as recorded by the BMS: Bosch use a separate battery tester to determine actual capacity, which takes several hours by cycling the battery in real time.Is that really the current capacity of the battery relative to its capacity when new,

or is it just an indication of how much of the current capacity the charge has reached?

If the first that's great; does it also apply to Bosch batteries?

None of the on-board so-called "capacity" gauges are any better than a crude indicator, and I doubt Kalkhoffs are any different. If a battery has an expected life of 500 cycles to 80%, and the BMS has recorded 100 cycles in use, then the battery has 80% capacity left and 4 of the 5 LED's light.

I've got several (6) German BMZ batteries: The cells are certainly quality, but the circuitry employed is pretty standard; there's no additional BMS magic and it certainly isn't any cleverer than the rest that I've seen.

Here's the real-time Bosch battery capacity tester video @soundwave originally posted some time ago:

What makes this different from BMS cycle counting is that it's testing the actual battery capacity in real-time through a charge/discharge cycle.

The OP's issue at 9 years old is AGE, not cycles.

What makes this different from BMS cycle counting is that it's testing the actual battery capacity in real-time through a charge/discharge cycle.

The OP's issue at 9 years old is AGE, not cycles.

True of so many members hereHere's the real-time Bosch battery capacity tester video @soundwave originally posted some time ago:

What makes this different from BMS cycle counting is that it's testing the actual battery capacity in real-time through a charge/discharge cycle.

The OP's issue at 9 years old is AGE, not cycles.

Thanks everybody.

I think I’ve been lucky for the battery to last this long, and the motor.

From what I can make out this particular motor is prone to giving up which makes me reluctant to get a new battery.

Such a shame. It’s a lovely bike, never had anything go wrong.

Oh well, nothing lasts for ever, so, thanks again.

Happy peddling.

Thakery

I think I’ve been lucky for the battery to last this long, and the motor.

From what I can make out this particular motor is prone to giving up which makes me reluctant to get a new battery.

Such a shame. It’s a lovely bike, never had anything go wrong.

Oh well, nothing lasts for ever, so, thanks again.

Happy peddling.

Thakery

peter can service the motor.

Impulse

www.ebikemotorcentre.com

www.ebikemotorcentre.com

Impulse

- 2.0 & 2.3 £224.97*

- Evo & Evo RS £252.62*

Repair & Overhaul Service (New) - eBike Motor Centre (Performance Line Bearings)

Within the UK we offer a full repair and overhaul service for Bosch, Brose, Impulse, Mahle, Panasonic and Yamaha ebike motors. Please note: We do not currently support Shimano motors. How to Send us Your Motor If you can, remove your motor or have your local bike shop remove it for you, then...

www.ebikemotorcentre.com

www.ebikemotorcentre.com

- For my 36v bottle battery I knocked up (as in a basic construction) a battery capacity tester as seen in one of the pics below.

- The schematic diagram shows a battery that is connected (point A) to a wattmeter and then switched through to a resistive dummy load.

- My battery is nominally 10Ah but I know this figure is usually obtained by typically running the battery down to something like 2.5v whilst in practice a LVC (Low Voltage Cutoff) of 30-31v is more likely.

- So I set the XH-M609 to 31.v and discharged the battery. On first discharge a couple of months after use, the recorded amp-hours was 9.75Ah.

- Some 5,000Km later the measured capacity is 9.3Ah - so still at 95% of the original reading.

- As has been said above, the LED battery level indicators are complete pants so in my battery I replacd it with a little DVM module so I can see in real time what the battery voltage is.

- On top of that I also use the capacity tester to check on how many amp-hours I use to recharge the battery after a ride. This is achieved by connecting the charger to point A and the battery to point B. Results vary but you get a good idea of what total miles you might achieve if you were to cycle on to the LVC point.

- The power conversion rate in this mode is around 90%, ie. if the charger disipates 10Ah then the battery has been charged by 9Ah

- Useful data for those with an interest and for a cost of around £20 or less.

How difficult would it be to make a device which sits between the ebike battery and charger, accepts a ebike battery charger barrel connector, connects to the ebike battery via a barrel connector, monitors the voltage from the charger and shuts it off completely after the ebike battery has balanced, to prevent fires caused by ebike batteries continuing to be charged once full?

- That's a bit beyond my expertise (such as it is).

- I would guess you somehow need to monitor the current drawn by the battery as during the balancing process the current drops gradually to zero. If this state could be detected and made to trigger a relay or something.......?

- I've taken a simple approach to dealing with not having chargers on all night and that is a 3 pin plug in count down timer that is easily set by just pressing one button to determine how long before disconnecting what ever is plugged into it, ie the charger.

- Less that £20 off Amazon.

I've used Wilko's even cheaper variant with the tricky segments, trouble is I got distracted with other things and forgotten it's plugged in a few times, and the whole charging cycle cycle charging commenced again the following day after it switched off. I was hoping there was another electronic solution which didn't involve a little computer monitoring and managing the switchings on and off. The program could have easily accessible user assignable setting options by way of a small number of buttons and a small screen, to set how long after lowest voltage reached (or define at which voltage to immediately switch off at), that it continues to charge for balancing: none, one hour or n minutes etc. Manufacturers could build something into chargers which did the same at less expense, with their economies of scale, thereby preventing some fires. It's a gripe, but for now my cheapo Wilko timer will do, or I could simply use my digital timer (with it's almost invisibly tiny LCD screen - which also contains a lithium-ion battery lol) and assign a charging period within just that one day of the week, or just get a one shot timer as others have linked previously.Here's the timer link on Amazon - £10.99

Last edited:

Why don't you use something like this: You preset the end voltage you want, and the charger is turned off when the battery gets there.How difficult would it be to make a device which sits between the ebike battery and charger, accepts a ebike battery charger barrel connector, connects to the ebike battery via a barrel connector, monitors the voltage from the charger and shuts it off completely after the ebike battery has balanced, to prevent fires caused by ebike batteries continuing to be charged once full?

You could set say 41v as a safe upper limit to terminate the charge where you could top it off a little bit more before you ride if you wanted, or say set to 36-37v if you want a safe long-term storage charge.

I've seen them for about £10 before - maybe a little more nowadays (apologies for my crude image cutting and pasting).

£8.92

...or with a shell for £13.49

Lead-acid Battery Charging Controller Protection Board Switch XH-M604 12V/24V UK | eBay

Find many great new & used options and get the best deals for Lead-acid Battery Charging Controller Protection Board Switch XH-M604 12V/24V UK at the best online prices at eBay! Free delivery for many products.

www.ebay.co.uk

...or with a shell for £13.49

'caused by an e-bike charging overnight'

www.belfastlive.co.uk

www.belfastlive.co.uk

Fire Service warning after blaze 'caused by e-bike charging overnight'

They recently attended the incident in Belfast