Hi all

I am tempted to increase the top speed by replacing my 36v battery to 48v lifepo4 battery.

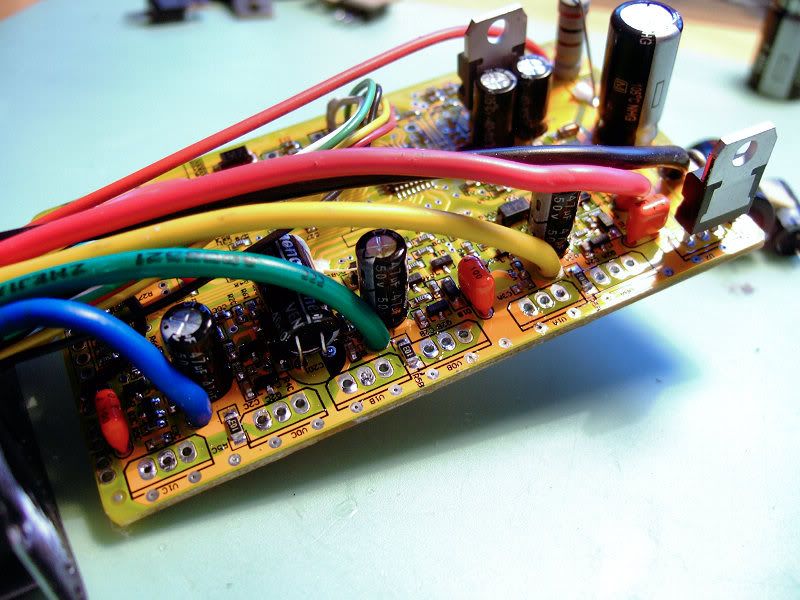

My controller is ku65 but I am not sure if it can take 48v lifepo4 battery without blowing it.

I remember the full charged 48v battery has around 52.4v not sure the capacitor in the controller can take that voltage.

Does anyone know if the ku65 can take 48v lifepo4 without problem?

I am tempted to increase the top speed by replacing my 36v battery to 48v lifepo4 battery.

My controller is ku65 but I am not sure if it can take 48v lifepo4 battery without blowing it.

I remember the full charged 48v battery has around 52.4v not sure the capacitor in the controller can take that voltage.

Does anyone know if the ku65 can take 48v lifepo4 without problem?