There are 2 problems in this thread that really have similar causes and solutions.

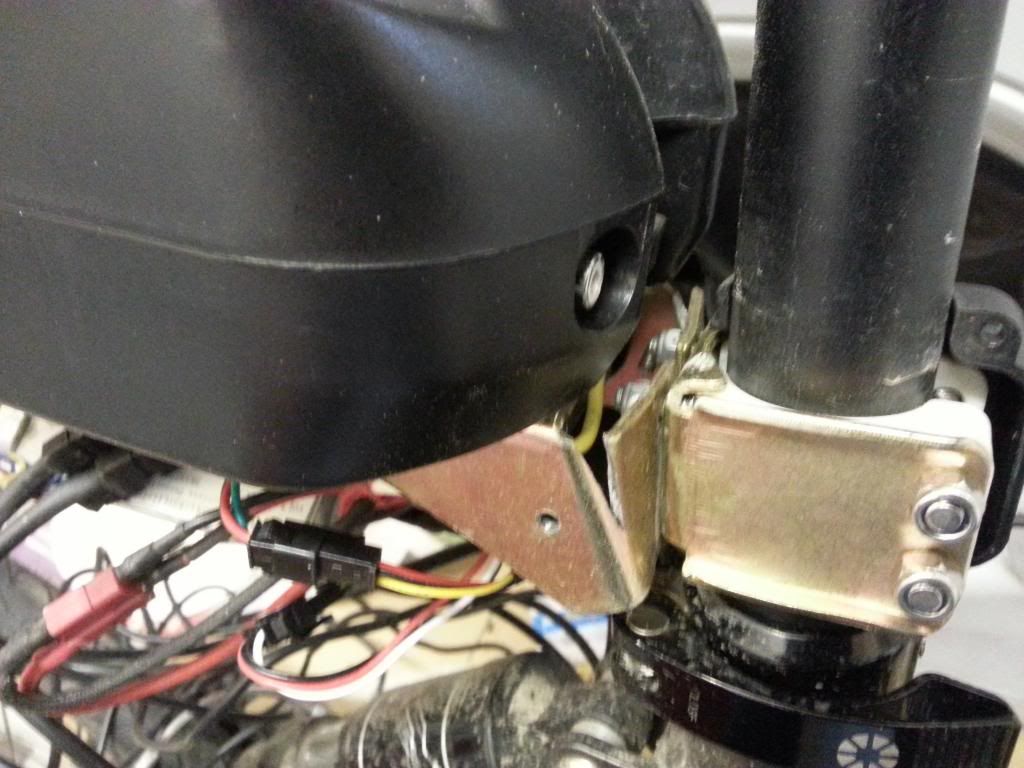

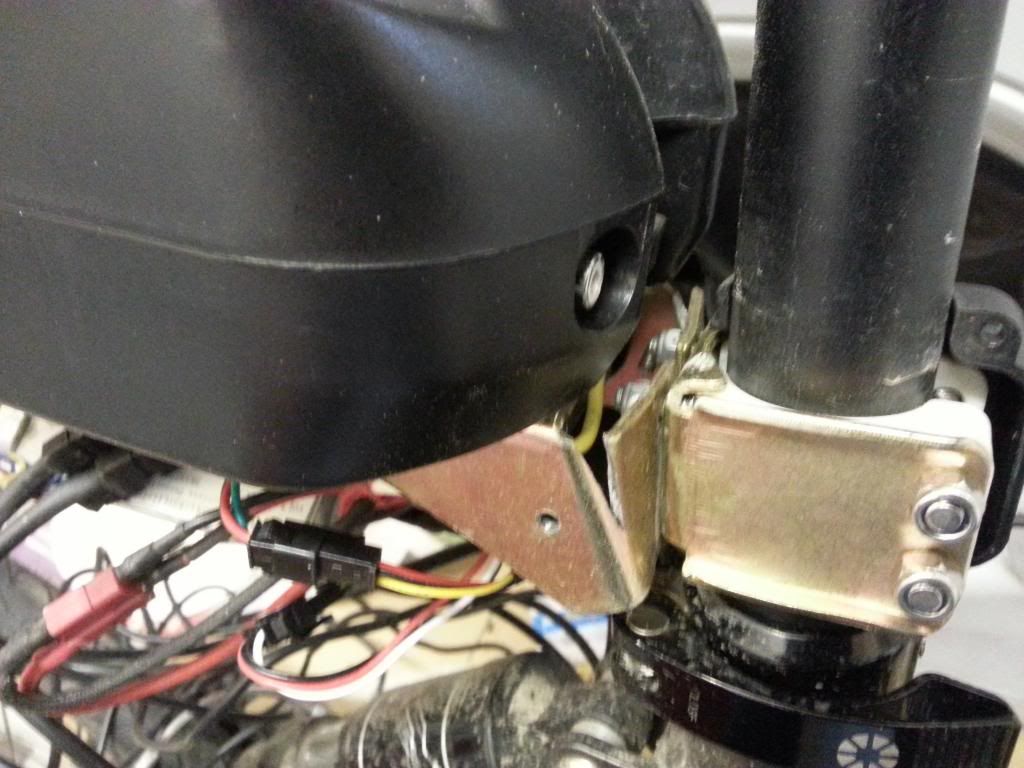

1. The frog battery mount will crack where it mates with the seatpost if you incorrectly use the handle on the battery to lift the bike. It will also crack at the same place if you do a lot of rough off-road riding due to the battery being cantilevered on the seat post and having no outboard support.

2. The seat post needs to extend down into the seat tube,beyond the junction of the top tube/rear upper stay/seat tube,ideally by 30mm minimum-but the outside diameter of the seat post is often much smaller than the inside diameter of the seat tube,so the seat post can still float inside the seat tube and cause stress at the point where the seat tube extends above the aforementioned junction-if you look at D8VEH's above photo of failure of the seat tube,this point is obvious.

If you add frog batteries and cantilevered racks this increases the stress at that point.

The solutions are...

1. Fit a rack which is supported onto the rear stay,if possible attach the frog battery to this rack

2. Machine a thin walled sleeve that has an od to fit the id of the seat tube and an id to fit the od of the seat post.,glue this in place.

3. Use the longest seat post available

4. Never extend the seat post such that the lower end of the seat post is above the 'point 30 mm below the junction'and preferably further down in the seat tube.

5. Never pick the back end of the bike up using the handle of the frog battery.

If anyone has damaged their bike like D8VEH's photo,I have designed a solution which I would be pleased to supply..it saves scrapping the frame.

KudosDave